Sand Blasting Machine Manufacturer in Sri Lanka

Specifications of Sand Blasting Machine Manufacturer in Sri Lanka

| Machine Capacity | 150 kg – 1000 kg |

| Air Consumption | 45 CFM – 135 CFM |

| Blast Hose Length | 5 m – 10 m |

| Cleaning Rate | 3 m²/hr – 12 m²/hr |

| Abrasive Tank Material | Mild Steel / Stainless Steel |

| Nozzle Material | Tungsten Carbide / Boron Carbide |

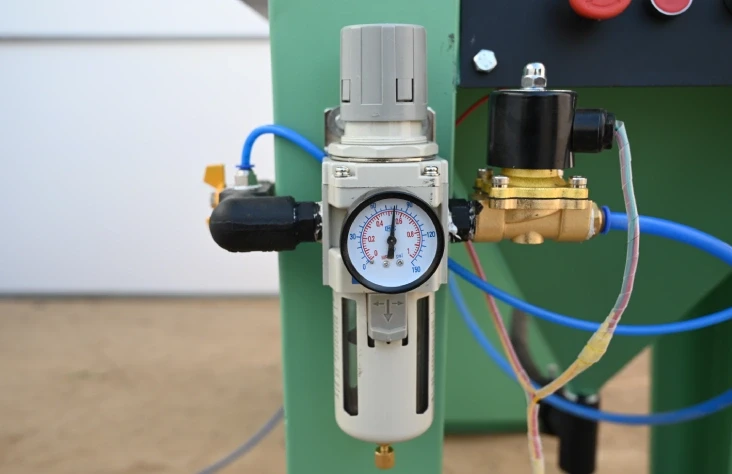

| Required Pressure | 4 Bar – 7 Bar |

| Operation Mode | Manual / Semi-Automatic / Automatic |

Application of Sand Blasting Machine Manufacturer in Sri Lanka

- Ship Maintenance & Marine Industry: Removal of marine growth and corrosion from ship hulls and offshore structures.

- Construction Sector: Surface preparation of steel beams, gates, and concrete structures for coating or painting.

- Vehicle Restoration: Cleaning and restoring metal parts, frames, and underbodies in automotive repair shops.

- Industrial Maintenance: Cleaning turbines, boilers, and pipelines in power plants and manufacturing plants.

- Decorative Etching: Creating frosted or engraved designs on glass, tiles, or metal surfaces for architectural or commercial use.

Introduction to Sand Blasting Machine

A sand blasting machine is a critical tool used in surface preparation and finishing. It works by propelling abrasive particles at high velocity to clean or texture surfaces, making them ideal for further treatment like painting, coating, or bonding. In Sri Lanka, where industries such as marine engineering, construction, automotive maintenance, and metal fabrication are growing rapidly, sand blasting machines are playing a key role in maintaining equipment, enhancing product quality, and prolonging material life.

Due to Sri Lanka’s humid, coastal climate, surfaces are especially prone to rust and corrosion. A sand blasting machine offers an efficient, eco-friendly solution to remove rust, paint, grease, and other surface contaminants—boosting both performance and appearance.

Working of Sand Blasting Machine

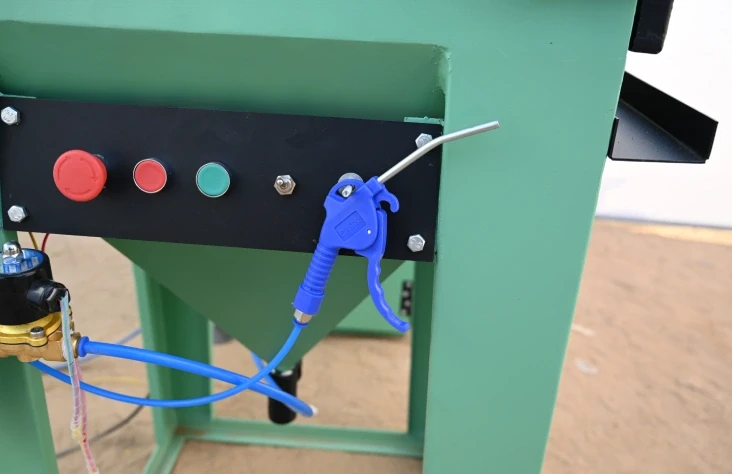

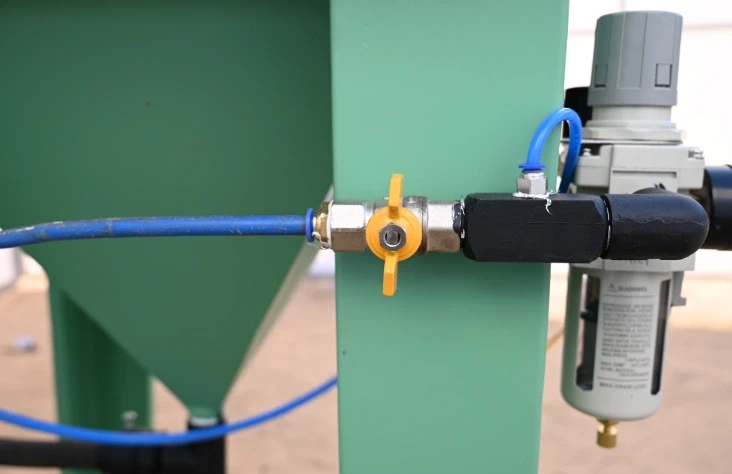

The operation of a sand blasting machine involves several core components: an abrasive tank, compressed air system, blast hose, and nozzle. When in use, abrasive media (such as garnet, aluminum oxide, or glass beads) is loaded into the tank. Compressed air is then used to forcefully eject the abrasive through a nozzle toward the surface being treated.

This impact removes unwanted material from the surface, effectively cleaning, smoothing, or roughening it depending on the application. The entire system can be manually operated or semi-automated depending on industrial needs. In Sri Lanka, where cost-efficiency and multi-purpose use are essential, portable and cabinet-based machines are most in demand.

Types of Sand Blasting Machines

- Portable Sand Blasting Machine- These are mobile, versatile units used at construction sites, shipyards, and workshops. They are preferred for field use and can clean large structures like bridges, tanks, and vehicles.

- Cabinet Sand Blasting Machine- This type is ideal for precision cleaning in enclosed spaces. It prevents media spillage and dust generation, making it ideal for tool and die shops, metal parts cleaning, and intricate surface preparation.

- Automatic Sand Blasting Machine- Designed for high-throughput environments like mass manufacturing, these machines ensure consistent surface treatment with minimal manual intervention.

Types of Portable Sand Blasting Machines

- Pressure Pot Sand Blasting Machine- These machines store the abrasive under pressure, allowing for powerful and continuous blasting. They are widely used in industrial cleaning of steel structures and heavy machinery.

- Suction Sand Blasting Machine- A more cost-effective and lightweight system that uses the suction principle to draw abrasive into the blast stream. Ideal for light cleaning and general maintenance work.

Types of Sand Blasting Cabinets

- Suction Blast Cabinet- Uses a vacuum to pull abrasive into the gun. It’s suitable for lighter tasks like paint stripping, deburring, and small-scale part cleaning.

- Pressure Blast Cabinet- Uses compressed air pressure to blast media with greater force. Preferred in applications requiring aggressive cleaning and quicker turnaround times.

- Wet Blast Cabinet- Combines water with abrasive to minimize dust and static, making it suitable for operations where air quality or part integrity is a concern.

Sand Blasting Machine Price in Sri Lanka

The cost of a sand blasting machine in Sri Lanka varies depending on its size, capacity, and configuration. Portable models are more economical, making them suitable for general maintenance and small businesses. Larger cabinet and automated systems, while more expensive, offer higher precision and efficiency for industrial use.

To get an accurate price tailored to your needs, including delivery, installation, and training options, we recommend contacting our local distributor or sending us a detailed inquiry.

Why Choose Us as Your Sand Blasting Machine Manufacturer

- Custom-Built for Sri Lankan Industries: We understand local industrial challenges such as high humidity, fluctuating power, and varying abrasive availability, and tailor our machines accordingly.

- High Durability & Efficiency: Our machines are constructed using wear-resistant materials and are designed for prolonged industrial use.

- Versatile Product Range: Whether you're a small workshop or a large industrial firm, we have machines that fit your budget and application.

- Technical Support in Sri Lanka: We offer remote and on-site support, training, and spare parts availability to ensure long-term performance.

- Trusted Global Manufacturer: With years of experience in international markets, we bring proven technology to local conditions.

© 2025 All right reserved.