Sand Blasting Machine in Kuwait

Specifications of Sand Blasting Machine in Kuwait

| Product | Sand Blasting Machine |

| Abrasive Tank Capacity | 150 L / 300 L / 500 L / 1000 L |

| Working Pressure Range | 4 – 8 Bar (58 – 116 PSI) |

| Nozzle Material | Tungsten Carbide / Boron Carbide |

| Power Source | Electric (220V/440V) / Pneumatic |

| Abrasive Media Supported | Garnet, Steel Grit, Aluminum Oxide, Glass Beads |

| Material | Mild Steel / Stainless Steel |

| Air Requirement | 20 – 85 CFM depending on capacity |

| Safety Features | Deadman Handle, Pressure Relief Valve, PPE Kit |

| Brand | Micro Blaster |

| Color | As per client requirement |

| Delivery Time | 15-20 Days |

| Production Capacity | 4 Machine |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Sand Blasting Machine in Kuwait

- Surface Cleaning: Sand blasting is widely used to clean various surfaces by removing: Rust, Dirt, Oil stains, Old paint, Scale, and corrosion.

- Paint & Coating Removal: Used to strip away old or damaged paint coating to prepare the surface for repainting or recoating. Common in: Automobiles, Ships, Industrial machinery, Aircraft parts.

- Surface Preparation: Before applying paint, epoxy, or powder coating, the surface must be roughened or cleaned. Sand blasting helps to: Improve coating adhesion, extend coating life, and avoid coating failures.

- Rust and Corrosion Removal: Kuwait’s coastal environment accelerates corrosion. Sand blasting removes rust from: Metal pipelines, Oil rigs, Shipping containers, Heavy machinery.

- Deburring: after metal fabrication or machining, sand blasting is used to remove sharp edges, burrs, and machining marks. Used for: Gears, Engine parts, Die-cast components.

- Etching and Engraving: Fine sand blasting machine allows engraving or texturing of surfaces like glass, stone, or metal for decorative purposes - examples: Personalized glass gifts, Nameplates, Architectural features.

- Restoration of Old Surfaces: Restores worn-out or aged surfaces by removing contaminants and revealing the original material underneath.

- Concrete Surface Treatment: Sand blasting roughens concrete to improve bonding before applying finishes or overlays. Used in: Road and bridge repairs, Parking structures, Floor refinishing.

- Ship Maintenance and Hull Cleaning: Marine vessels use sand blasting to remove marine growth, rust, and old paint from: Ship hulls, Propellers, Ballast tanks.

- Oil and Gas Equipment Maintenance: In Kuwait, sand blasting is critical for cleaning offshore rigs, maintaining oil storage tanks, preparing wellheads, and drilling equipment.

- Military and Aerospace Applications: Used to clean and maintain: Fighter jet bodies, Tanks and armored vehicles, Aircraft landing gear.

Sand Blasting Machine in Kuwait: A Complete Guide

A sand blasting machine is equipment used to clean, smooth, or shape a surface using high-speed abrasive media like sand. The process is also known as abrasive blasting. Sand blasting machine in Kuwait is commonly used for cleaning metal surfaces, removing paint or rust, and preparing surfaces for coatings.

Sand blasting machine in Kuwait is one of the most popular surface preparation equipment used in various industries. In Kuwait, the demand for sand blasting machines is growing due to the country's active construction, oil & gas, and industrial sectors.

A sand blasting machine (also called an abrasive blasting machine) is a mechanical equipment that cleans or prepares a surface using a high-speed stream of abrasive material. This process is known as sand blasting or abrasive blasting.

The machine pushes abrasive particles (such as sand, garnet, or steel grit) through a nozzle using compressed air. When these particles hit the surface, they remove unwanted layers like rust, old paint, oil stains, or scale. This process is especially useful in Kuwait, where metal corrosion is common due to salty air, sandstorms, and extreme temperatures.

Subsequently, we will explain a complete understanding of sand blasting machines in Kuwait, what they are, how they work, where they are used, and how to choose the right one.

Basic Components of a Sand Blasting Machine

- Blasting Tank: Holds the abrasive material.

- Sand Blasting Nozzle: Directs the abrasive onto the surface.

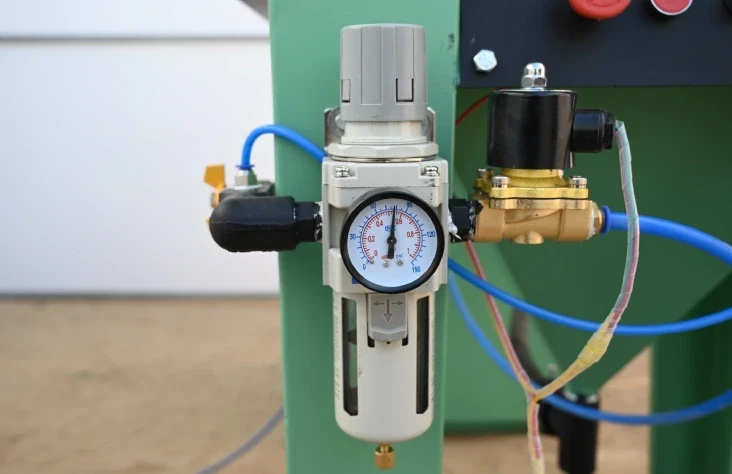

- Air Compressor: Provides the air pressure needed to blast the material.

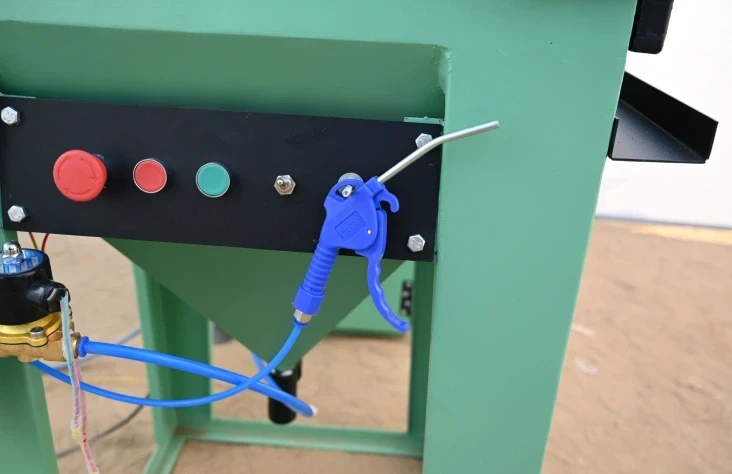

- Remote Control Valve: Regulates the flow of the abrasive.

- Sand Blasting Hose: Transfers the material from the tank to the sand blasting nozzle.

- Protective Gear: Safety gear for the operator, including masks and gloves.

Why is Sand Blasting Popular in Kuwait?

Kuwait has a dry, dusty climate and a large number of industrial projects. The local environment causes faster corrosion of metal surfaces, especially near the sea. This increases the need for surface treatment solutions like sand blasting.

How Does a Sand Blasting Machine Work?

A sand blasting machine works in a simple yet powerful way:

- Abrasive is loaded into a tank or container.

- An air compressor generates high-pressure air.

- The air mixes with the abrasive material.

- The mixture is forced through a sand blasting hose and nozzle.

- The abrasive hits the surface and cleans or roughens it.

- This method is faster and more effective than manual cleaning methods like wire brushing or chemical treatments.

Major Uses of Sand Blasting Machine in Kuwait

- Oil & Gas Industry: Cleaning pipelines, tanks, and drilling equipment.

- Marine Industry: Removing rust and old paint from ships and boats.

- Construction: Preparing steel structures and concrete for painting or coating.

- Automotive: Restoring old cars and machinery.

Popular Sand Blasting Abrasives in Kuwait

The abrasive media is a key part of the sand blasting process. Some of the commonly used abrasives in Kuwait include:

- Garnet Sand: Popular for its low dust and high cutting speed.

- Aluminum Oxide: Used for hard metals and aggressive cleaning.

- Glass Beads: Ideal for delicate surfaces and a smooth finish.

- Steel Grit: Heavy-duty abrasive media for removing tough rust and coatings.

- Silica Sand: Traditional but less used now due to health risks.

In Kuwait, the sand blasting machine is more than just industrial equipment it is a vital equipment across multiple industries. Whether you're cleaning corroded metal, preparing concrete, or restoring old machinery, Micro Blaster offers a fast, effective, and affordable sand blasting machine.

Sand Blasting Machine Price in Kuwait

Micro Blaster is the best sand blasting machine manufacturer in Kuwait and also a supplier of sand blasting equipment worldwide. Sand blasting machine price in Kuwait depends on the size, type, and capacity of the sand blasting machine. Our sand blasting machine price in Kuwait is low compared to others. We also offer all types of abrasive blasting machine, sand blasting machine, grit blasting machine, portable sand blasting machine, sand blasting cabinet, granite engraving machine, laser rust cleaning machine, sand blasting machine spare parts, sand blasting nozzle, sand blasting helmet, remote control valve, dustless blasting machine, sand blasting hose, pinch valve, mixing tube, etc.

© 2025 All right reserved.