Sand Blasting Machine in Saudi Arabia

₹40K-5Lakhs

Specifications of Sand Blasting Machine in Saudi Arabia

| Product | Sand Blasting Machine |

| Material | Mild Steel and Stainless Steel |

| Machine Type | Portable and Cabinet |

| Grade | Automatic, Semi-Automatic, Manual |

| Cleaning rate | 3-5 sqr. mtr/ hr |

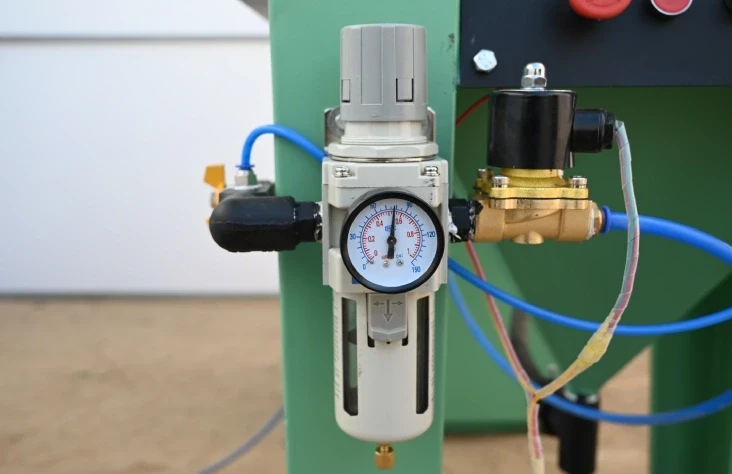

| Compressed air (80 psi) | 45 Cfm to 217 Cfm |

| Voltage | 220-240 V | 50 Hz |

| Max. Pressure | 10000 PSI |

| Brand | Micro Blaster |

| Color | As per client requirement |

| Delivery Time | 2-3 Weeks |

| Production Capacity | 4 Machine |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Sand Blasting Machine in Saudi Arabia

- Oil & Gas Industry: Saudi Arabia’s oil business pipelines, rigs, and storage tanks need blasting to remove corrosion and scale, and to prep for protective coatings.

- Construction: Sand blasting readies steel beams and concrete surfaces for painting, waterproofing, and repair in infrastructure projects.

- Marine & Shipyards: Ships and port equipment gather rust, algae, and salt. Blasting cleans and prepares surfaces for repainting, improving efficiency and safety.

- Automotive: Used in body shops for removing old paint and rust, and for cleaning engine parts, chassis, and wheels.

- Metal Fabrication: Blasting removes burrs post-cutting, cleans welding slag, and optimizes surfaces before coating or assembly.

Introduction to Sand Blasting Machine

Sand blasting machine in Saudi Arabia is powerful equipment that shoots abrasive media, like steel grit or garnet, at high speed to remove rust, paint, grime, and scale. They also prepare surfaces for coatings. Saudi Arabia has a booming industrial sector covering oil & gas, construction, marine, automotive, and manufacturing. To keep equipment and structures clean and ready, businesses use sand blasting machines in Saudi Arabia.

A sand blasting machine (also called an abrasive blasting machine) forces abrasive particles onto surfaces at high speed using compressed air or a spinning wheel. It’s a fast and effective method to:

- Remove old paint, rust, and coatings

- Clean metal, concrete, wood, and glass

- Roughen surfaces to improve coating adhesion

- Polish or shape materials for decoration

These machines are more reliable and faster than traditional methods like scraping, sanding, or chemical cleaning, especially in demanding Saudi conditions where surfaces often get corroded due to heat, dust storms, and salty coastal air.

Types of Sand Blasting Machines

Portable Sand Blasting Machine

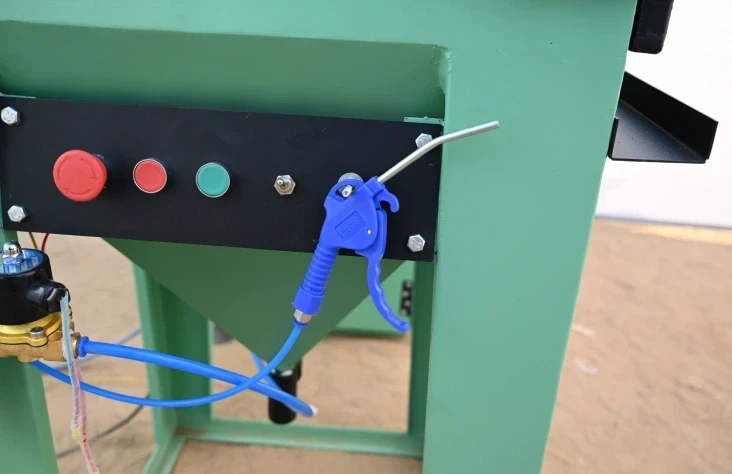

A portable sand blasting machine is a movable unit used for on-site surface cleaning. It consists of a blasting pot, a hose, a nozzle, and a compressor. Compressed air pushes the abrasive material (like sand, steel grit, or garnet) through the nozzle to clean surfaces.

Automatic Sand Blasting Machine

This type uses CNC or robotic controls for automated blasting, often integrated into production lines. Pre-programmed machines handle part feeding, blasting, and movement with minimal human input.

Cabinet Type Sand Blasting Machine

This is a closed chamber machine where the operator works using built-in gloves and views the process through a clear window. Abrasive is recycled inside the cabinet. The operator places parts inside and uses the internal nozzle to clean them safely. The types of sand blasting cabinets are as follows:

Pressure Sand Blasting Cabinet

Pressure sand blasting cabinet uses a pressurized tank to push abrasive material at high speed onto a surface. It’s one of the most powerful and effective types. Air pressure builds in a sealed tank (blast pot), and the abrasive is forced out at high velocity through a nozzle.

Suction Sand Blasting Cabinet

Also known as siphon blasting, this machine uses a suction gun to draw abrasive from a hopper using air pressure. Compressed air moves through the gun and creates suction that pulls abrasive material up into the stream, blasting the surface.

Wet Sand Blasting Cabinet

Wet blasting cabinet mixes water with abrasive media to reduce dust and cool the blasting surface. The water-abrasive mix is sprayed using high-pressure air. It creates less dust and prevents surface warping due to heat.

Common Abrasives Used in Sand Basting Machine

The type of abrasive matters:

- Steel grit/shot: Heavy-duty; best for thick rust

- Garnet sand: Low-dust, eco-friendly; widely used in Saudi Arabia

- Aluminum oxide: Aluminum oxide abrasive is a hard abrasive for metal prep

- Glass beads: Gentle and shiny finish

- Plastic/soda: For delicate surfaces (e.g., plastics)

- Copper slag: Economical sand alternative

In Saudi Arabia, sand blasting machines are essential tools across industries like oil & gas, construction, marine, automotive, and fabrication. They offer fast, efficient cleaning and surface preparation. When choosing a machine, consider type, abrasive compatibility, safety features, after-sales support, and environmental standards.

Sand Blasting Machine Cost in Saudi Arabia

We are one of the leading sand blasting machine manufacturers and suppliers of sand blasting machines in Saudi Arabia, offering high-performance abrasive sand blasting machines at competitive costs. Our machines are designed to meet international standards and serve a wide range of industries, including oil & gas, construction, marine, automotive, and fabrication. We proudly supply sand blasting machines across Saudi Arabia and export worldwide. Our sand blasting machine cost in Saudi Arabia are highly competitive, without compromising on quality. We ensure cost-effective solutions with long-lasting performance and low maintenance. We also offer all types of abrasive blasting machines, such as sand blasting machines, shot blasting machines, and grit blasting machine, etc.

© 2025 All right reserved.