Sand Blasting Machine in India

Specifications of Sand Blasting Machine in India

| Blast Tank Capacity | 50 to 500 liters |

| Nozzle Material | Tungsten Carbide, Boron Carbide |

| Abrasive Media Supported | Garnet, Aluminum Oxide, Steel Shot, Glass Beads, Copper Slag |

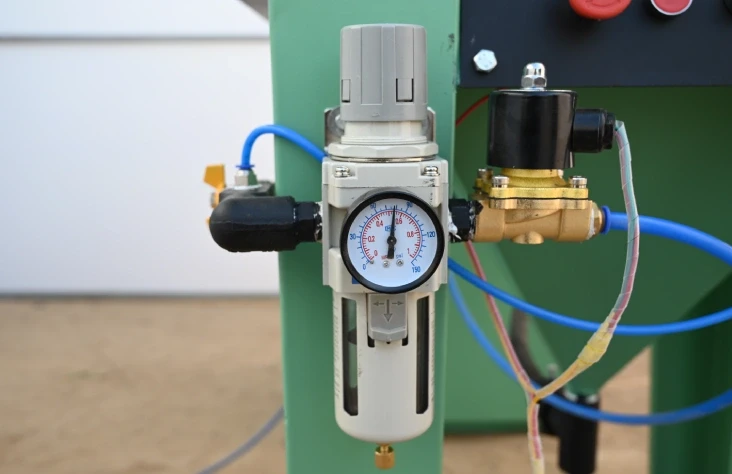

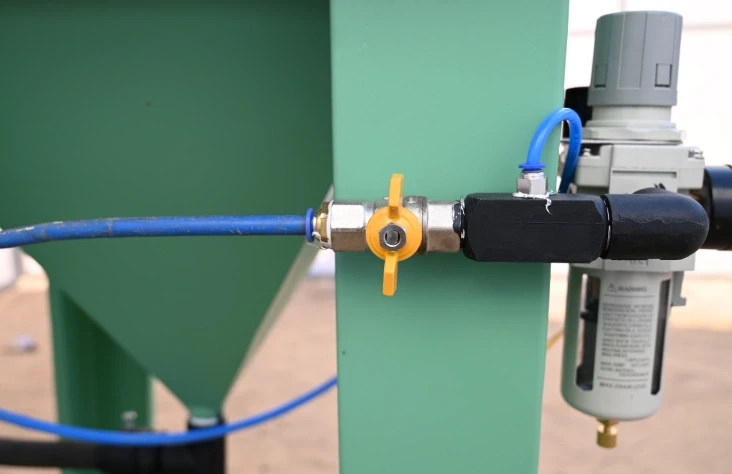

| Operating Pressure | 80 – 120 PSI |

| Air Requirement | 5 – 12 CFM |

| Power Source | Electric or Pneumatic |

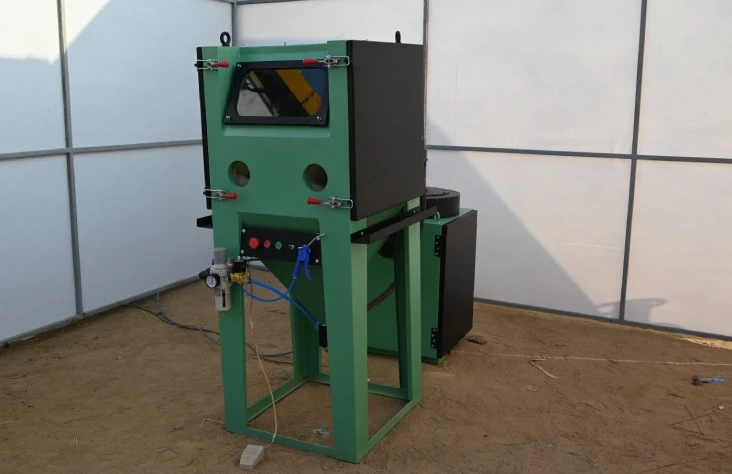

| Machine Configuration | Portable, Cabinet, or Automatic |

| Dust Collector Option | Manual Bag Filter, Cartridge Filter, Cyclone Separator |

| Automation Levels | Manual, Semi-Automatic, Fully Automatic |

| Suitable Industries | Automotive, Railways, Oil & Gas, Fabrication, Aerospace, Shipyards |

Introduction to Sand Blasting Machine in India

A sand blasting machine is a specialized piece of equipment used in surface treatment operations, particularly to clean, prepare, or restore surfaces by forcibly propelling abrasive media such as sand, garnet, or glass beads. In India, where industries such as automotive, metal fabrication, railways, oil and gas, shipbuilding, and infrastructure are expanding rapidly, sand blasting machines have become an essential part of manufacturing and maintenance workflows.

These machines ensure surface cleanliness and precision, which are crucial before applying protective coatings like paint, powder coating, or galvanizing. Indian manufacturers, including exporters and OEM suppliers, increasingly rely on advanced sand blasting technologies to maintain international standards of production and surface finishing.

Working of Sand Blasting Machine

Sand blasting machines operate by pressurizing air in a compressor and then directing that compressed air through a blast hose and nozzle. Abrasive material stored in a tank or hopper is carried along with this air stream and blasted onto the target surface. The kinetic energy from the abrasive particles scrapes, polishes, or removes unwanted layers like corrosion, scale, or old paint.

The machines are built with safety features, dust collection systems, and media recovery setups to minimize environmental impact and ensure operator safety. In India, where varying climates and work conditions exist, machines are often customized to ensure they can handle high dust loads, high humidity, and power fluctuations.

Types of Sand Blasting Machine

- Pressure Blasting Machine – This is the most powerful type, where abrasive media is pushed by compressed air from a pressurized vessel. It is used in industries like shipyards, construction, and defense.

- Suction Blasting Machine – Also known as a siphon system, it pulls media using vacuum suction. It is ideal for small to medium applications such as component cleaning and tool refurbishment.

- Wet Blasting Machine – Water is mixed with abrasive to reduce dust and heat. It is used for applications where surface damage or contamination must be avoided.

- Automatic Sand Blasting Machine – These machines integrate with production lines and offer high speed, automation, and consistency, ideal for mass production in automotive and electronics industries.

Sand Blasting Machine Price in India

Sand blasting machine prices in India span a wide range depending on the machine's size, type, and level of automation.

-

Portable models are available in the low price range, making them suitable for small businesses or basic cleaning tasks.

-

Industrial blasting cabinets and semi-automatic systems fall into the medium price range, offering a balance of efficiency and cost.

-

Fully automatic, high-capacity machines with advanced features are typically in the high price range, designed for large-scale operations and continuous production environments.

We provide flexible options tailored to your operational scale—whether you're a local workshop or a large industrial plant.

Why Choose Us as Your Sand Blasting Machine Manufacturer in India

We are one of India's most trusted and experienced sand blasting machine manufacturers, known for quality engineering, reliable service, and competitive pricing. Here’s what sets us apart:

-

In-house production with strict quality assurance

-

Machines designed to handle Indian industrial environments and conditions

-

Low to high-range options to suit every scale and budget

-

Fast delivery and service support across all regions of India

-

Customization based on your material type, production speed, and finishing requirements

-

Long-term technical support, spare parts supply, and annual maintenance contracts

-

Experience working with top companies in automotive, railways, aerospace, and oil & gas sectors

© 2025 All right reserved.