Recent Blogs

Latest Tags

Complete Guide of Copper Slag Abrasive

Copper slag is a secondary material in the copper slag production process. When copper is deposited in a foundry, it solidifies the top layer of dirt...

What is Grit Blasting Machine Price in Australia?

Grit Blasting Machine is a surface preparation machine that is frequently used in a wide range of industries for a variety of purposes. An abrasive me...

What is Sand Blasting Nozzle?

A sand blasting nozzle accelerates the air and abrasive because the mixture exits the tip of the hose. The taper and length of the nozzle's channel an...

Application of Shot blasting machine

Shot blasting machine is the method of high velocity propelling a stream of abrasive media against a surface under very high pressure to smooth a roug...

Shot Blasting Machine Manufacturer in United States

The shot blasting machine is equipment that is specially designed and produced for individual customer requirements.

How a Shot Blasting Machine Works?

This machine is used to remove unwanted corrosion and metallic waste on the surface of finished goods. This is done for making the surface uniform and...

What are Abrasive Blasting Media And Its Benefits?

Abrasive blasting is the method by which an abrasive media is shot through a blasting nozzle with the help of compressed air. The abrasive used differ...

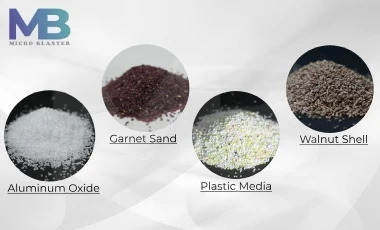

What are the types of abrasive media used in the blasting machine?

Abrasive media is a blasting material used to clean substrates during the removal process. Using compressed air, abrasive media is propelled towards a...

What is a Portable Sand Blasting Machine?

A Portable Sand Blasting Machine is a blasting machine that we can easily move from one place to another. This machine is very economical and gives a...

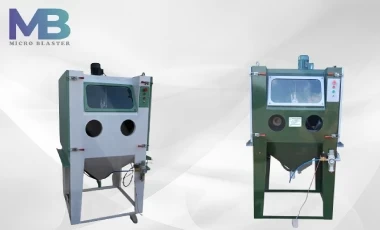

Types of Sandblasting Cabinet

Mini and Large Sandblasting Cabinet is a cabinet consisting of many components use for sandblasting the substrate surface. Sandblasting is a process i...

What is Abrasive Blasting Cabinet?

An abrasive blasting Cabinet is a cabinet consisting of many components utilized for shot blasting the substrate surface. A shot blasting cabinet is k...

What is Wet Blasting Cabinet and its working?

Wet Blasting Cabinet is based on the principle of Induction Suction. The important feature is that it has the capability to work with very fine partic...

What is the Pressure Blasting Cabinet and its Working?

A Pressure Blasting Cabinet is a chamber of mild steel sheets that provides high-pressure sand/shot or grit blasting. It provides safety to the worker...

What is Suction Blasting Cabinet and its Working?

Suction Blaster Cabinet works on the induction-suction principle of abrasive delivery. Initially start the air compressor and fill the abrasive materi...

What is Sand Blasting Hopper?

In the Abrasive or Manual sandblasting hoppers, basically the mixture of air and sand has to impose with high speed and pressure on the surface of the...

What is the Difference Between Shot Blasting and Sand Blasting?

Shot blasting and Sand Blasting are both processes utilized in mechanical surface cleaning. Many industries that use metal apply these methods daily f...

What kind of abrasives can be used in sand blasting process?

Sand blasting is also known as abrasive blasting. Actually, it is the process of forcibly propelling a stream of abrasive material against a surface.

What is dustless Sand Blasting?

Dustless sand blasting is a process of prepping surfaces using a mixture of water and abrasives such as recycled glass bead, to remove old paint, dirt...

Twin Arc Spray Gun

A twin arc spray gun is a coating machine also known as an electric arc spray gun and thermal spray equipment. The equipment is a manipulator type and...

Gas Flow Meter

The gas flow meter is a highly accurate and reliable instrument for regulating and measuring the flow of both oxygen and fuel gas in a manual powder a...

Boiler Tube Coating

A coating technology to prevent boiler tube failures due to external erosion, abrasion, corrosion & high-temperature oxidation.A Reliable boiler tube...

Aluminum Spray Gun

The aluminum spray gun is used for the coating process with aluminum wire on the surface of the substrate to avoid the risk of rust and oxidation.

Copper Spray Metalizing Gun

In copper spray metalizing if oxygen and gases are used in metalizing it is called the copper flame spray gun. In this process, oxygen is used with ac...

Flame Spray Gun Manufacturer

Flame Spray Process is basically the spray of molten metal like zinc, copper, aluminum on the surface for providing a coating.

Thermal Spray Gun

Thermal Spray Gun is a group of coating methods in which finely divided metallic or nonmetallic materials is stored in a molten or semi-molten positio...

Flame Spray Gun

Flame Spray Gun is the kind of approach in which uses an oxy-fuel flame to melt the wires.

Powder Flame Spray

Powder Flame Spray Process is basically the spray of molten metal like zinc, copper, aluminum on the surface for providing a coating.

Arc Spray Gun

Electric arc spraying is a thermal spraying process it is using an electric arc between two consumable electrodes of the surfacing materials as the he...

Zinc Spray Gun

This spray gun sprays out from the gun to have a zinc coating on the subject. This gun uses compressed air or motor-driven.

Metalizing Gun Price

The metalizing gun price is being used now predominantly as a maintenance tool for repair and rebuilding of machinery.

Metco Metalizing Gun

Wire flame spray Gun Metco 16E (Metco Metalizing Gun) uses a single wire that is entered in a jet flame.

Metalizing Gun

Metalizing Gun is a general name given to a thermal spray coating process that is used for coating metal on the product plane

Metal Spray Gun

A Metal spray gun is used for the thermal coating process which uses a single wire, cord, and powder for coating. This feed material is melted in an o...

Wire flame spray gun and how does wire flame spray gun work?

Wire Flame Spray Gun is the set of approaches in which is used an oxy-fuel flame to melt the wires.

Thermal Spray Coating and different types of thermal spray coating?

Thermal spray coating refers to a number of processes in which are coated to improve functional performance. Many types of coating methods can be appl...

What is Sandblaster Cabinet?

Sandblaster cabinet is a machine that has a cabinet and it is a closed form of the machine.

What is Sandblaster Nozzles and Applications?

A sandblaster nozzles bore shape determines its blast pattern. Sandblaster nozzles generally have either a straight bore or a restricted venturi bore....

Blasting Booth

Micro Blaster is Leading Manufacturer, Supplier, and wholesaler of Blasting Booth. Our largest Blast room manufacturing companies in United States, Ge...

Blast Room System

Blast Room System design is customized as per customer demand it can completely automate or manually type.

Tumblast Shot Blasting Machine

Tumblast Shot blasting machine made in several sizes, models and has various applications for various cleaning and peening purposes.

Shot Blaster Cabinet

Shot blaster cabinet is another type of shot blaster machine which has a cabinet and is a closed form of the machine.

Portable Grit Blasting

Portable grit blasting machine used to soften rough surfaces, this machine removes rust or corrosion from metal surfaces, gives a surface clean or sha...

Portable Sand Blasting

Portable Sand blasting is a machine that uses abrasive materials with air pressure to clean or prepare surfaces for painting or other coatings.

What is Portable Shot Blasting Machine?

Portable shot blasting machine or mobile shot blasting is the machine that can be movable from one place to another easily.

What is Grit Blasting? How Grit Blasting Machine Works?

Grit Blasting is a process which smoot a surface with the help of high velocity steel abrasive material.

What is Sand Blasting? How sand blasting machine works?

Sand blasting is basically applied to clean the exterior surface of any metal or component, mainly for the metallic exterior.

Shot Blasting

Shot Blasting is a process which smooth a surface with the help of high-velocity steel abrasive material. The shotblaster method helps in obtaining th...

The Different Types of Shot Blasting Machines and Their Applications

The shot blasting machine is a vital tool for surface preparation in a wide range of industries. There are several different types of shot blasting ma...

Guide to Understanding Steel Shot

The steel shot is great for deburring and peening stampings and fabrications. Its properties make it ideal for eliminating corrosion from the surfaces...

Steel Shot for Shot Blasting

Steel shot is commonly used as an abrasive material for shot blasting. Shot blasting is a surface preparation technique that involves blasting a surfa...

Steel Shot For Shot Peening

Steel shot is also commonly used for shot peening, a process that involves bombarding a metal surface with small, spherical shots to improve its fatig...

Granite Engraving Machine for Sale

A Granite Engraving Machine for sale is an approach of engraving a structure onto a difficult, normally facedown exterior by carving tracks into it ac...