Sand Blasting Machine in Myanmar

Specifications of Sand Blasting Machine in Myanmar

| Abrasive Tank Capacity | 150 L / 300 L / 500 L / 1000 L |

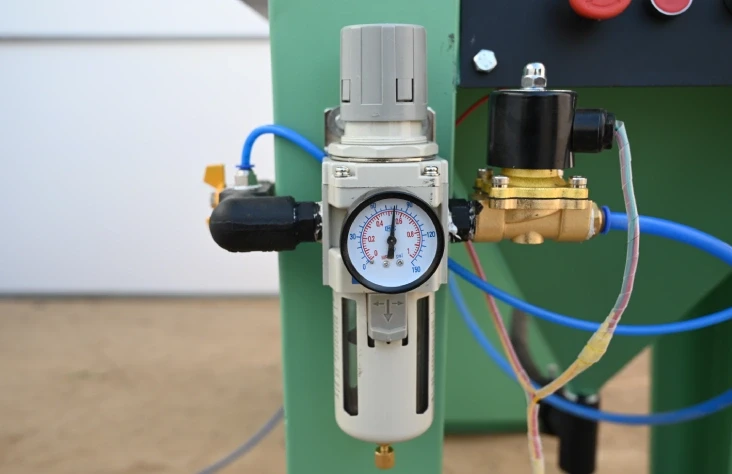

| Working Pressure Range | 4 – 8 Bar (58 – 116 PSI) |

| Nozzle Material | Tungsten Carbide / Boron Carbide |

| Power Source | Electric (220V/440V) / Pneumatic |

| Abrasive Media Supported | Garnet, Steel Grit, Aluminum Oxide, Glass Beads |

| Blast Hose Diameter | 19 mm / 25 mm / 32 mm |

| Dust Collection System | Dry Filter / Cyclone / Wet Scrubber |

| Air Requirement | 20 – 85 CFM depending on model |

Application of Sand Blasting Machine in Myanmar

- Shipbuilding and Marine Maintenance: Cleans ship hulls, containers, and marine equipment for repainting and corrosion protection.

- Steel Fabrication and Welding Preparation: Prepares steel beams, pipelines, and tanks by removing mill scale, grease, and coatings.

- Bridge and Infrastructure Projects: Used in roadwork, rail bridges, and water pipelines for pre-treatment before coating or inspection.

- Hydropower and Energy Projects: Cleans turbines, steel gates, and structural parts used in hydroelectric facilities.

- Automotive Workshops: Restores vehicle components, removing rust and old paint before repair and painting.

- Industrial Manufacturing: Used in tool cleaning, mold preparation, and finishing of metal parts and assemblies.

- Glass and Decorative Etching: Used to etch designs on glass or stone surfaces for architecture or signage.

A sand blasting machine is a powerful industrial tool used for cleaning, texturing, and preparing surfaces by blasting them with high-speed abrasive materials. It removes rust, old coatings, oil, contaminants, and surface imperfections to prepare metal, concrete, and stone surfaces for painting, coating, or welding.

In Myanmar, with the expansion of infrastructure, shipyards, industrial zones, and construction projects, the demand for reliable sand blasting machine has significantly increased. As a leading sand blasting machine manufacturer, we offer durable and efficient systems that meet local requirements—from industrial zones in Yangon to oil and gas facilities in the southern regions. Our equipment is engineered to operate effectively even in Myanmar’s humid, tropical conditions.

Working of Sand Blasting Machine

A sand blasting machine uses pressurized air to force abrasive particles like garnet, steel grit, or aluminum oxide through a blast nozzle. These high-velocity particles strike the surface and remove unwanted layers such as rust, paint, scale, or dirt, leaving a clean and roughened profile ideal for coatings or bonding.

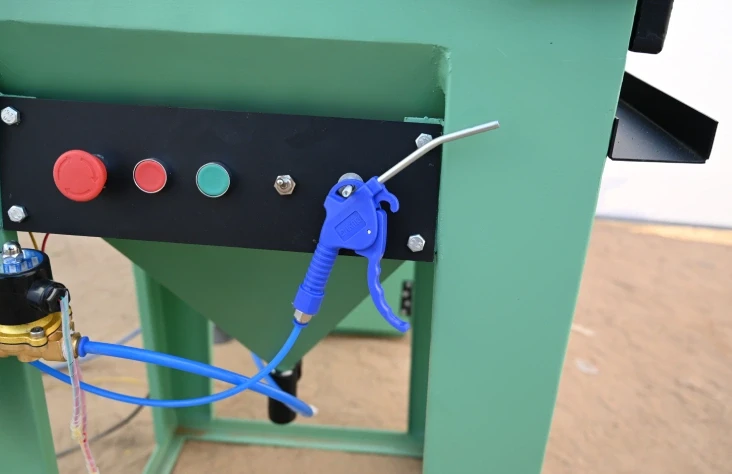

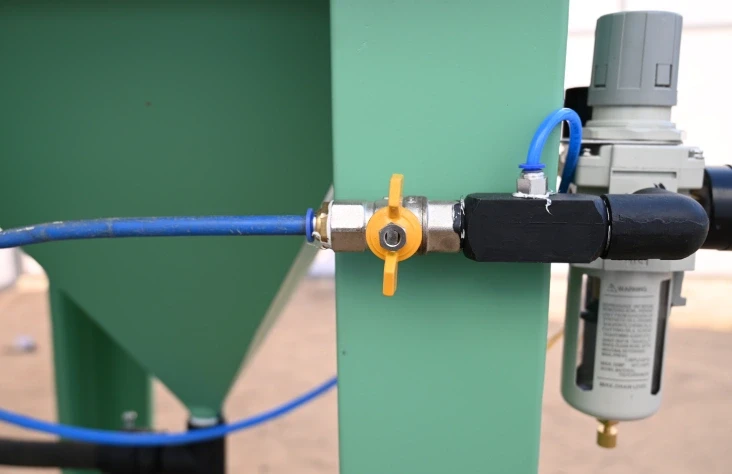

The system consists of an abrasive storage tank, control valves, air compressor, nozzle, and sometimes a dust collector. Once the system is activated, abrasive material is mixed with compressed air and discharged through the hose at high speed. The blasting intensity and finish can be controlled by adjusting the air pressure, nozzle type, and abrasive selection.

In Myanmar, these machines are commonly used in heavy equipment maintenance, shipbuilding, bridge renovation, and factory production environments where surface integrity is critical.

Types of Sand Blasting Machine

We manufacture and supply several models of sand blasting machines to suit diverse industrial needs across Myanmar. The types include:

- Pressure Blasting Machine: Uses a pressurized tank for high-speed abrasive flow—ideal for removing hard coatings and corrosion.

- Suction Blasting Machine: Draws abrasive through suction, suitable for precision work and small component cleaning.

- Wet Blasting Machine: Combines water with abrasives to suppress dust—suitable for indoor operations and sensitive environments.

- Automatic Sand Blasting Machine: Programmable and automated for batch operations and consistent surface finishes.

- Portable Sand Blasting Machine: Mobile units used on-site at construction locations, repair yards, and industrial plants.

- Sand Blasting Cabinet: Enclosed machines used for controlled blasting of small and medium-sized workpieces.

Types of Portable Sand Blasting Machine

Portable sand blasting machines are especially useful in Myanmar where mobility and flexibility are needed on construction sites, offshore platforms, and fabrication yards. We offer:

- Mini Portable Sand Blasting Machine: 50-liter tank; suited for touch-ups and light-duty tasks.

- Medium Capacity Portable Machine: 100-liter tank; used for general maintenance and workshop use.

- Large Capacity Portable Machine: 200-liter tank; built for shipyards, large steel structures, and continuous operations.

- Portable Pressure Blasting Machine: Ideal for high-impact surface treatment in industrial zones or steel factories.

- Wet Portable Blasting Machine: Used where dust suppression is necessary, such as near residential zones or indoor spaces.

Types of Sand Blasting Cabinet

Blasting cabinets are used across Myanmar in manufacturing, automotive, and aerospace industries where precision and cleanliness are essential. We offer the following:

- Suction Blasting Cabinet: Designed for detailed and low-pressure applications on small parts.

- Pressure Blasting Cabinet: Offers higher abrasion force for heavy-duty part cleaning.

- Wet Blasting Cabinet: Combines water and abrasive to reduce airborne dust—great for sensitive workpieces.

Automatic Blasting Cabinet: Integrated with turntables or conveyors to automate repetitive blasting tasks.

Sand Blasting Machine Price in Myanmar

The cost of a sand blasting machine in Myanmar varies based on capacity, application, automation level, material construction, and accessories. Since each requirement is unique—whether it's for light maintenance or industrial production—we provide custom quotations based on your operational needs, abrasive type, and work environment.

Please contact our technical team to get a personalized solution and quotation.

© 2025 All right reserved.