Suction Blasting Cabinet

Specifications of Suction Blasting Cabinet

| Machine Type | Suction type |

| Material | Mild Steel |

| Machine Type | Automatic, Manual |

| Usage | Surface Cleaning and abrasive sand recovery system |

| Cleaning rate | 3-5 sqr. mtr/ hr |

| Power | 1 Hp |

| Color | As per client requirement |

| Delivery Time | 15-20 Days |

| Production Capacity | 5 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Suction Blasting Cabinet

- For many coating, painting, and corrosion issues, suction sandblast cabinets offer the best cleaning, smoothing, and finishing option.

- They are best used to provide a decorative or aesthetically acceptable surface finish on a variety of materials.

- Depending on the type of blastings required, such as shot or sand blasting, the Suction Blasting Cabinet uses a variety of abrasives to remove impurities and rust.

- The Suction Blasting Cabinet provides an environmentally friendly blasting method for abrasive blasting since it collects all the tiny particles from the abrasive medium into the Dust Collector.

- The suction blasting cabinet's use of glass beads gives the metal object a brilliant finish.

- In small places, suction blasting cabinets are used to finish, texture, and clean surfaces while safeguarding both the environment and workers.

Sand Blasting Suction Cabinet is based on the Injection Suction principle of blasting. The industrial sandblast cabinet ensures non-stop working and no interruption in the blasting cycle. It is used for light and medium-size components / particles where the surface is to be cleaned or de-burred or to provide a fine matte finish. Suction sand blasting cabinet works on the Venture principle to make abrasive from a non-pressurized storage hopper to the blast gun where it is combined with the compressed air stream and propelled toward the work surface or blasting surface. Suction sand blasting machine is most clearly recognized by having two hoses (one for air and one for abrasive media) running to the blast gun.

When we are working with a sand suction-blast gun, it is easy to recognize, because it has two pipes attached to it, one providing compressed air and one abrasive shot blasting pipe (vacuum pipe) is taking media into the gun. Sand Pressure-blast nozzles have only one larger pipe to deliver a mixture of media particles and compressed air.

Suction Sand Blast Cabinet

The suction Sand blasting cabinet system uses the venture principle, integrating an air jet one half the inside diameter of the Sand blasting nozzle. This creates a -ve(negative ) pressure in the pipe that sucks the abrasive media into the gun body from the media containing hopper. A suction sand blaster can work continuously without shutdowns to refill abrasive media in the storage hopper and can be easily operated with multiple guns over multiple bodies.

Suction sand blast cabinets give the ideal cleaning, smoothing, and finishing solution to many coating, painting, and corrosion problems. They are ideally utilized for ensuring a decorative or naturally pleasing surface finish across many materials.

Suction systems generally have lower capital costs than a pressure blasting cabinet and use less compressed air, making them appropriate for smaller workshops or lower production environments.

Sand Blasting Suction Cabinet Features

- Suction sand blasting cabinets are of lower cost than similar-sized pressure blasting cabinets.

- Less air and abrasive consumption are there in suction abrasive blast gun as its air demand is governed by the abrasive air jet, which is almost half the size the same as the blast nozzle diameter.

- A suction blaster has far fewer moving parts and valves than a pressure abrasive blast unit, therefore, more easy maintenance and troubleshooting are possible there.

Continuous blasting is possible in a suction sand blasting cabinet because we need not think to refill the abrasive media containing hopper again and again in this, whereas in a pressure sand blast system the continuous blasting time is decided by the amount of abrasive media present in the storage hopper or pot present at one time.

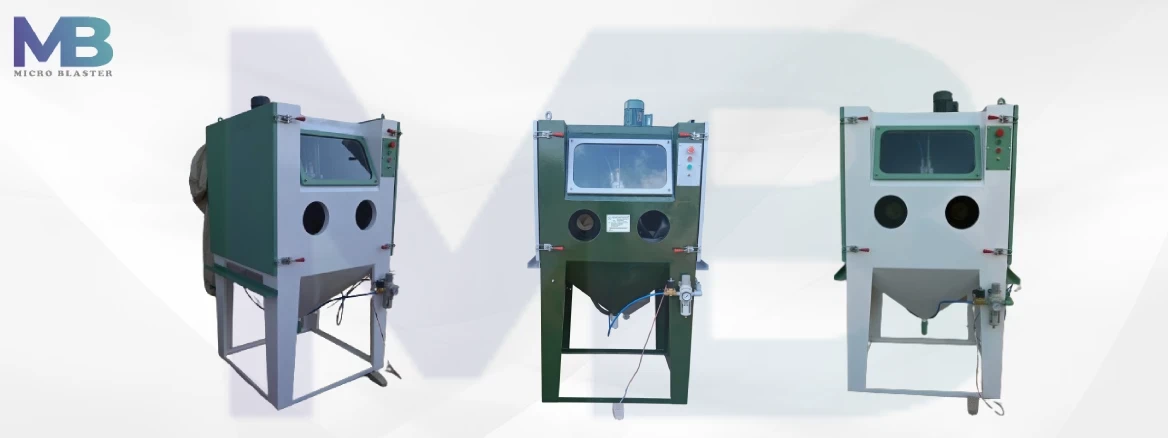

Sand Blast Cabinet Standard Models are :

- Sand Blast Cabinet SSB-6060

- Sand Blast Cabinet SSB-9182

- Sand Blast Cabinet SSB-12090

Sand Blasting Suction Cabinet Manufacturer

We manufacturer Suction Sand blasting Cabinet and Sand Blasting Suction Cabinet Manufacturer is a low price . Suction blasting cabinet for sale in countries such as United States, Germany, South Korea, Brazil, Mexico, United Kingdom, Gulf & Australia. We offer all cabinets type sand blasting machine, shot blasting machine, grit blasting machine, and abrasive media. Suction blast cabinet from Micro blaster automate production sequences and improve the work environment.

Suction Sand Blast Cabinet Price in United States, Germany, Gulf & Australia

Blaster is the No. #1 Manufacturers, Supplier and Exporter of Sand blasting Cabinet, Sandblasting Cabinet, Small & Large Sand Blasting Cabinet with the best quality in United States, Germany, Gulf & Australia. We offer all types of Sand Blast Cabinet, Shot Blasting Cabinet, Grit Blasting Cabinet, for Sandblasting Machine in United States, Germany, Gulf & Australia.

Related Product

© 2025 All right reserved.