Abrasive Blasting Machine

Specifications of Abrasive Blasting Machine

| Product | Abrasive Blasting Machine |

| Material | MS Steel |

| Power | 12.5hp |

| Voltage | 440V |

| Frequency | 50Hz |

| Machine Grade | Manual, Semi-Automatic, and Automatic |

| Color | As per client requirement |

| Delivery Time | 1-2 Weeks |

| Production Capacity | 5 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Abrasive Blasting Machine

- For painting preparation.

- For food process cleaning & maintenance.

- An abrasive blasting machine is used to clean & prepare steel also aluminum surfaces for coatings.

- For architectural component preparation.

- For wood & concrete surface restoration.

- For warehouse cleaning.

- For Railroad car preparation.

- For bridge construction, cleaning, maintenance, & painting.

- Abrasive blasting is utilized to prepare surfaces, like glass, before etching textures & designs.

- For Plastic injection mold cleaning.

- For clean & maintaining sand-casting molds.

- Bearings, shafts, & gears can utilize abrasive blasting for shot peening.

- For graffiti removal.

An abrasive Blasting Machine is equipment in which smallish angular & spherical particles are forced at a component by compressed air, & mechanical elevated velocity rotating wheels & water pumps. The blast media variety, shape, size, density, & hardness, chaperoned by media acceleration & magnitude of media, mixed accompanied by blasting spread from the job piece, grade of influence, & time cycles are consequential characteristics in the abrasive blasting machine process bits of knowledge.

An abrasive material is forcefully propelled against a surface under high pressure using an abrasive grit blasting machine, sometimes referred to as an abrasive blasting & sand blasting machine. The media, often referred to as abrasive blasting material, is driven against the surface by centrifugal wheels, compressed air, vapor streams (often steam), or a pressurized fluid (typically water).

The two most abrasive blasting techniques are sandblasting & shot blasting machine, which both use metal shot. Glass bead blasting, plastic media blasting (with plastic stock), and organic abrasive blasting with corncobs and walnut shells are examples of moderately abrasive blasting techniques.

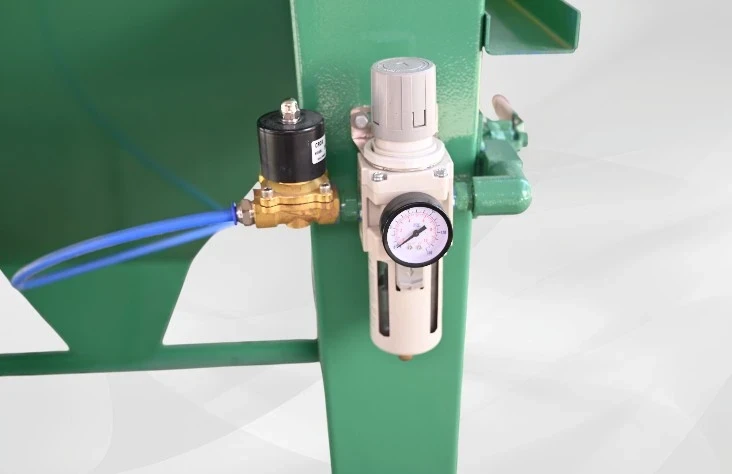

Abrasive Blasting Equipment

Abrasive blasting equipment is made to construct, recycle, & detention media, incorporate the portion to be blasted, & collect the dust from the blasting process. Elements can be processed separately as a collection process & can be automated along the system.

Abrasive blasting systems commonly include three important components: an abrasive container (i.e., blasting pot); a propelling device; & an abrasive sand blasting nozzle & nozzles. The actual equipment employed turns to a considerable distance on the exhaustive application & type(s) of abrasive.

Abrasive blasting is the suitability of abrasive material to clean & texturize a material like metal & masonry. Garnet Sand is considerably widely utilized blasting abrasive. Additional abrasive materials incorporate coal slag, smelter slags, mineral abrasives, metallic abrasives, & synthetic abrasives. Industries that utilize abrasive blasting comprise the shipbuilding industry, the automotive industry, also other industries that implicate surface preparation & painting.

Abrasive Blasting Machine Working Principle

Three basic techniques can be utilized to project the abrasive toward the surface standing cleaned: air pressure; centrifugal wheels; & water pressure.

- Air blast (& dry) systems utilize compressed air to move abrasive employing either a suction-type & pressure-type process.

- Centrifugal wheel systems employ a rotating impeller to mechanically move abrasive by a mixture of centrifugal & inertial forces.

- Finally, water (wet) blast approach employs either air pressure & water pressure to move an abrasive slurry toward cleaned surface.

Abrasive materials utilized in blasting can typically be categorized as sand, slag, metallic steel shot & steel grit, synthetic, also others. The cost & properties auxiliary accompanied by the abrasive media dictate its application.

Quartz silica sand is typically utilized for abrasive blasting where reclaiming is not conceivable, like in unrestricted abrasive blasting strategies. Sand has a preferably elevated decomposition rate, which can outcome in consequential dust generation. Worker orientation to unrestricted crystalline silica is apprehension when silica quartz sand is utilized for abrasive blasting.

Coal & smelter slags are typically utilized for abrasive blasting at shipyards. Black Beauty, TM which is composed of granulated slag from coal-fired utility boilers, is a of course engaged slag. Slags contain the usefulness of lower silica content, while contain been demonstrated to discharge additional pollutants, inclusive of unstable air contaminants (HAP), into the air.

Metallic abrasives incorporate cast iron shot, cast iron grit, & steel shot. Cast iron shot is difficult & brittle & is delivered by scattering molten cast iron into a water bath. Cast iron grit is delivered by crushing oversized & inconsistent particles developed in the course of the manufacture of cast iron shot. Steel shot is constructed by mismanaging molten steel. Steel shot is not as difficult as cast iron shot, and is much better stable. In an Abrasive blasting machine, these materials generally can be reclaimed & reused.

In Abrasive Blasting Synthetic abrasives, like silicon carbide & aluminum oxide abrasive, are evolving as widespread expedients for abrasive media. These abrasives are additionally enduring & construct less dust than sand. In an Abrasive blasting machine, these abrasive media generally are recycled & reused.

Other abrasives contain mineral abrasives (like garnet, olivine, & staurolite), cut plastic, glass beads, crushed glass, & nutshells. As accompanied by metallic & synthetic abrasives, these additional abrasives are naturally engaged in methodologies where the material is recycled. Mineral abrasives are declared to construct exceedingly less dust than sand & slag abrasives.

The variety of abrasive utilized in a particular application is usually exhaustive to the abrasive blasting method. Dry blasting is usually accomplished accompanied by sand, metallic grit & shot, aluminum oxide (alumina), also silicon carbide. Wet blasters are employed accompanied by sand, glass beads, & additional materials that stay balanced in water.

Abrasive Blasting Machine Price

Abrasive blasting machine price depends on the type, size, and abrasive storage capacity of an abrasive blasting machine in United States, Germany, Gulf & Australia. An abrasive blasting machine price also depends on the cleaning rate of an abrasive blasting machine. our abrasive blasting machine price is low compared to others. We provide sand blasting machine, stone shot blasting machine, dry abrasive blasting machine, wet blasting machine, Glass bead blasting machine, shot peening machine, granite engraving machine, thermal spray gun, wire flame spray gun, HVOF gun, tungsten carbide coating, thermal spray coating, abrasive media, copper slag, plastic media, glass beads, steel grit, cast steel shot, thermal spray powder, mineral powder, gypsum powder, bentonite powder, limestone powder, air compressor, & dust collector, etc.

Related Product

© 2025 All right reserved.