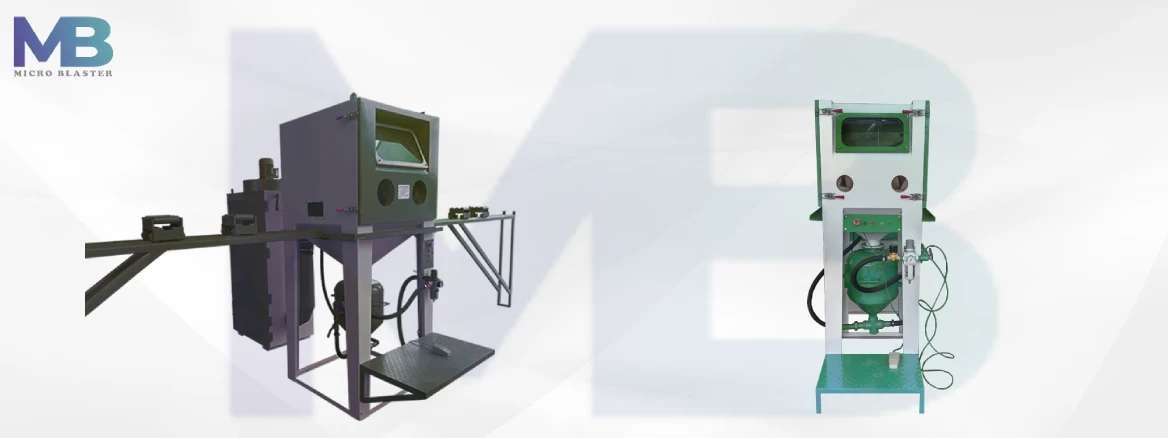

Pressure Blasting Cabinet

Specifications of Pressure Blasting Cabinet

| Cleaning rate | 10 sq. mtrs/ hr |

| Motor Power | 1.5 Hp |

| Machine Type | Automatic / Manual |

| Usage | Rust Removal/ Surface Preparation |

| Pressure | 25 CFM at 80 PSI |

| Voltage | 110 Volt |

| Frequency | 60 HZ |

| Color | As per client requirement |

| Delivery Time | 2-3 Weeks |

| Production Capacity | 3-5 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Pressure Blasting Cabinet

- Remove rust, mill scale, heat scale and carbon buildup from metals

- Strip paint, powder coating, plating and anodising from parts for rework

- Eliminate burrs, parting lines, flashing and other

- Defects from castings and injection-molded parts

- Extract residual sand from castings

- Sand Removal

- Tube Cleaning

- Beautify steel, stainless steel, aluminum, brass and other metals with a matte finish

- Etch artwork and lettering into glass, stone, plastics, metal and other material

- Clean release agents and material buildup from molds

Pressure Sand Blasting Cabinet

Pressure sand blasting cabinet works on the direct pressure principle of blasting. When high abrasive velocity produces by pressure sandblaster which results in completing the job at a faster rate. A pressure container bolted under a hopper of a sandblast cabinet for automatic abrasive refilling arrangements. For high efficiency of dust collection, a tubular fabric bag dust collector, with a generous filter area is attached with the blaster cabinet as a standard feature. A manual shaker is provided for shaking. A high-Pressure sandblaster cabinet is recommended for fast cleaning, removal of corrosion and heavy rust using coarse abrasives. All types of coarse and medium-sized abrasives can be used depending on the application.

Obtaining a 5 to 10 times higher output (compared to suction feed) direct pressure blasting cabinets operate with one hose connected to the sand blasting nozzle. As a small sandblaster pot pressurizes the abrasive equal to the transportation air pressure, the abrasive material simply ‘falls’ (by means of gravity) into this air stream and is propelled towards the object. So, In this way,

the compressed air is only used for transporting the abrasive (without having to suck it up as well).

Good visibility and effective dust containment is achieved by the powerful dust extracting system which depending on the abrasive type and application, dust extraction can be optimized by applying automatically cleaned filter cartridges or a cyclone separator.

Pressure Blast Cabinet Available in three standard models:

- APB-9182

- APB-12090

- APB-150120

Options available on request:

- Higher output blast guns in place of standard.

- ON / OFF fitted with optional accessories.

- Reverse jet cartridge filter dust collectors.

- Foot-operated treadle switches for blasting.

- Motorized bag-shaking arrangement.

Powerful benefits of pressure blasting Cabinet

- Simple setup of pressure blast cabinet and abrasive amount

- Easy start/stop blasting with large foot pedal

- great working view through a full-width window and effective dust removal.

- Sufficient access possibilities with large side-door

- Easy disposal of collected dust in hopper

Automatic filter cleaning

- Better blasting value

- Realizing a 60 – to 99% higher work speed (compared to suction feed)

- Most abrasives can be used (also the ‘heavy ones’ like stainless steel shot or chilled iron grit

- Optimal surface providing for further painting- and gluing processing

- Adds a nice cosmetic finish

Quality includes

- Wear-resistant abrasive metering valve and blasting nozzle

- Neither dust nor abrasive pollution of the surrounding (work) area.

- Durable, powder-coated cabinet and extractor

- The rubber lining protects cabinet- and abrasive from wear

Better pressure blasting economics

- Affordable pressure blasting cabinet for most industrial branches because Gritco’s special mini blast pot can be placed directly under the sand blasting hopper

- Eliminated production downtime through better pre-treatment

Related Product

© 2025 All right reserved.