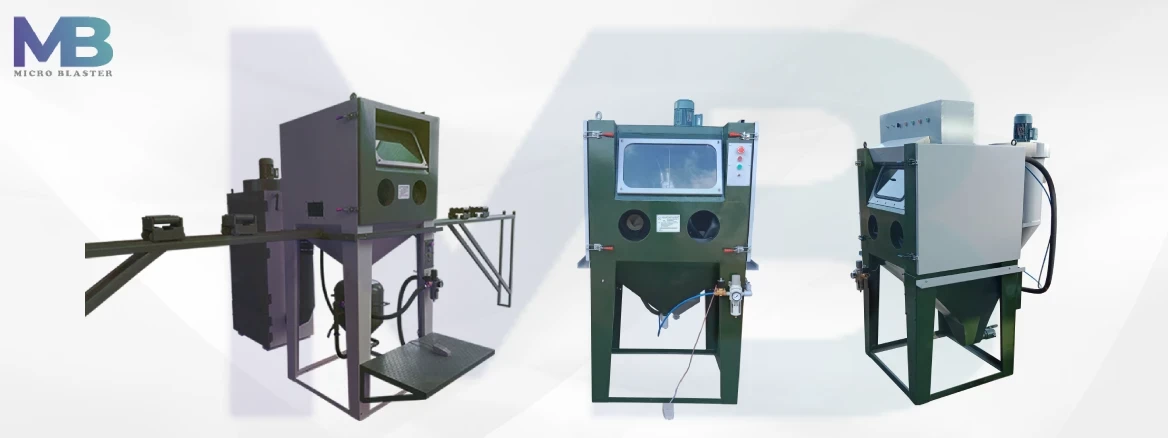

Sand Blasting Cabinet

Specifications of Sand Blasting Cabinet

| Material | Mild Steel |

| Machine Type | Pressure, Suction & Wet blasting cabinet |

| Grade | Automatic, Manual |

| Usage | Surface Cleaning and abrasive media recovery system |

| Voltage | 220 V |

| Frequency | 50 Hz |

| Cleaning rate | 3-5 sqr. mtr/ hr |

| Power Consumption | 0.5 hp to 1.5 hp |

| Color | As per client requirement |

| Delivery Time | 15-20 Days |

| Production Capacity | 4 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Sand Blasting Cabinet

- Removes rust – mill – heat scale and carbon buildup from metals

- Strip paint, powder coating, plating, and anodizing from parts for rework

- Eliminate burrs, parting lines, flashings, and other defects from castings and injection-molded parts

- Extract residual sand from castings

- Beautify mild steel, stainless steel, aluminum, brass and other metals with a uniform matte finish

- Etch artwork and lettering into glass, stone, plastics, metal and other materials

- Clean release agents and material buildup from molds

Sand blasting cabinet is another type of sand blasting machine which has a cabinet and is a closed form of the machine. In that closed part blasting of contaminants as well as recycling of sand blasting grit takes place. There are many different functions which are included like cleaning, recycling as well as the collection of dust particles too. In this sand blasting cabinet, there is a window from where the operator can see what is going on in the process; there is an opening door from where the blaster material or blaster surface is kept inside the cabinet.

As sand blasting grit is used as the abrasive material in the blasting process thus to avoid visibility dust collector are even connected with the sand blasting cabinets. In sand blasting cabinets the operator does not require any safety gadgets like a safety suit, mask or sand blasting helmet, shoes, blasting gloves, etc. as the whole process is performed inside the sand blast cabinet. This makes an eco-friendly, cost-effective, and pollution-free environment.

Specifications of Sand Blasting Cabinet

| Description | MB 6060 | MB 9182 | MB 12090 |

| Working chamber(mm) | (l)600x(w)600x(h)600 | (l)900x(w)910x(h)900 | (l)900x(w)1200x(h)900 |

| Door opening(mm) | (w)500x(h)500 | (w)730x(h)675 | (w)800x(h)800 |

| Overall dimension (mm) | (l)1500x(w)800x(h)1660 | (l)1400x(w)1070x(h)2000 | (l)1700x(w)1365x(h)2570 |

| Compressed air required(cfm) | 17 | 20 | 47 |

| Cleaning area (sq. mt/Hr) | 4-7 | 4-7 | 15-21 |

| Nozzle (mm) | 5/6 | 5/6 | 10 |

Types of Sand blasting Cabinet :

- Suction Blasting Cabinet

- Pressure Blasting Cabinet

- Wet Blasting cabinet

Suction Blasting Cabinet

Suction blasting cabinets are less expensive and easier to use than pressure blasting cabinets. They can also keep blasting without having to pause for media re-fills. When compared to a pressure system, the blasting velocity is substantially lower, despite the lower output rates. The suction system is an excellent alternative when initial cost and maintenance are important issues.

Pressure Blasting Cabinet

Pressure Blasting Cabinets are used for cleaning difficult work. When compared to suction blasting, pressure blasting delivers more abrasive Velocity for faster impact and intensity, and can enhance your production rate by three times. Media used is steel abrasive, sand, garnet, aluminum oxide, glass bead, etc.

Wet Blasting Cabinet

A wet blasting cabinet can utilise very fine abrasive, as little as 5 microns. Wet blasting takes place on the job when fine abrasive particles are combined in water and pumped to a nozzle as slurry. The slurry is then exposed to compressed air in the blast gun and wet blasting takes place. The slurry is fed into the blast gun at positive pressure using the glandless slurry pump.

The pump is resistant to corrosion. De-bering intersecting holes in precision pieces that are inaccessible by any other means is done in wet blast cabinets. For degreasing and finishing of various aero and vehicle components, the finest machined surface can be super polished without causing harm to sharp edges or perfect tolerances.

Parts and Consumables used in a Sand Blasting Cabinet

Because of the intense blast medium, sand blasting cabinets are prone to self-destruct. Blaster parts are consumable, and as abrasive or media flow over or through them, they will wear down over time.

The blast media or abrasive grits are, of course, consumable. Steel shot, ceramics, and aluminium oxide are examples of blast media that can be recycled a hundred times or more. Only one use of soda, dry ice, sand, and coal slag is made.

Parts in abrasive blasters, wheel blasters, and shot peeners must be evaluated for wear on a regular basis. When the inner diameter of the nozzle or the geometry of the throwing blades changes, the blasting process’ efficiency can be jeopardised.

Sand Blasting Cabinet Include:

- Sand Blasting Guns / Blast Guns

- Sand Blasting Nozzle / Blast Nozzles

- Blast Wheel Parts – Blast Wheel Blades, Cages, and Impellers

- Wear Plates

- Pressure Regulators

- Sandblaster Valves – Air inlet valves, abrasive metering valves, shut-off valves, media mixing valves, and pop-up valves

- Blast Cabinet Windows

- Blast Cabinet Floor Grating

- Blast Hose

- Blast Room Floor Grating

- Deadman Controls, Handle, and Valves

- Foot pedals

- Dust Collectors Filters

- Media Separator Screen and Parts

Optional accessories for above models:

- Manual/Motorized Turn Table

- Manual/Motorized Job trolley

- Motorized Tumble basket

- Track extension for Job trolley

- AC Drive for speed variations

Benefits of Sand Blasting Cabinet

- A blasting procedure that is both efficient and quick.

- Blasting with no interference.

- Because of the good air circulation, there is good visibility.

- Cabin with no foundation and a small footprint.

- For effective abrasive cleaning, use a cyclone.

- Metering cylinder for optimal abrasive metering.

Sand Blasting Cabinet Manufacturers in United States, Germany, Gulf & Australia

Micro blaster is the leading Manufacturer, Supplier & Exporter of Sand Blasting Cabinet in United States, Germany, Gulf & Australia. We have a large range of different types of sand blasting cabinets such as, Suction Blasting Cabinet, Pressure Blasting Cabinet, Wet Blasting cabinet, Bench Top Sand Blasting Cabinet, etc in United States, Germany, Gulf & Australia at a low price for sale.

Dry and wet blasting cabinets are available in our variety of blast cabinets. We have injector cabinets and pressure blasting cabinet for dry blasting. We also have blast cabinets that are specifically intended for finishing 3D printed plastic or metal products.

Do you need a competent blast cabinet and have high expectations for the blasting process? The best results come from Micro Blaster blast cabinets.

Our Packaging/Payment and Shipment Details

| Delivery Time | 1-2 weeks from the date of confirmation of Purchase Order and Advance. |

| Production Capacity | 12-15 Nos. Per Annum |

| Packaging Details | Poly Packaging |

| Shipment Mode | By Air By Road By Cargo |

| Payment Terms | Cash Cheque DD Credit Card |

Because of their durable design, great finishing, high durability, and extended practical life, our given items have won a lot of popularity in the market. We create these products using high-quality raw materials and cutting-edge technology to provide our customers with remarkable results. Our unwavering commitment to high-quality manufacture and delivery has resulted in a sizable customer.

Related Product

© 2025 All right reserved.