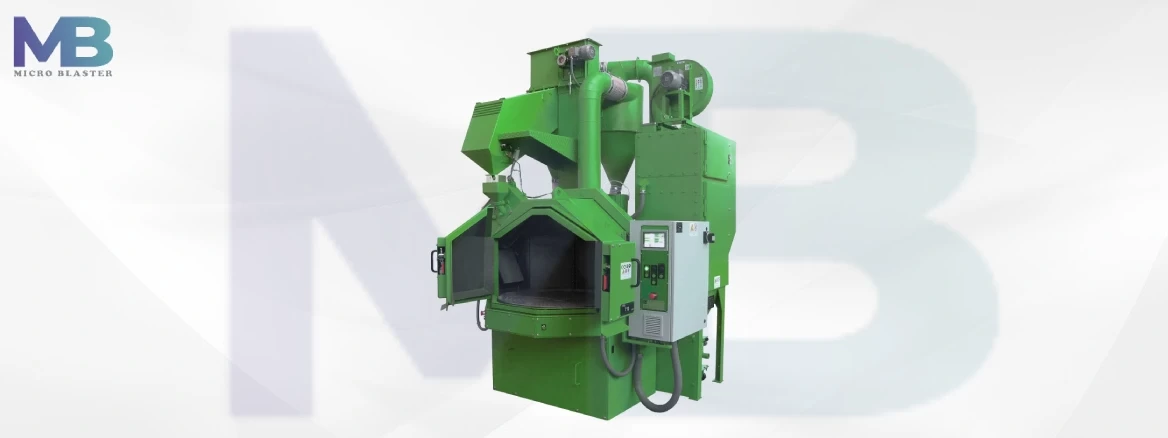

Table Type Shot Blasting Machine

Specifications of Table Type Shot Blasting Machine

| Dia of swing table | 750 mm - 1200 mm |

| Type of dust collector | Fabric bag dust collector /Reverse pulse jet pleated filter type dust collector. |

| cleaning of dust bags | Motorized shaking\ pulse jet air |

| The approximate shot flow rate | 4.5 -9 Tons/Wheel/Hour |

| Shot Velocity | 70-89 Mtrs./Sec. |

| Shots Consumption Approx. | 1.875 Kgs/Hr./Wheel |

| H.P. of Blast Wheel | 7.5 - 15Hp |

| R.P.M. of Blast Wheel | 2800 - 2400 |

| Shot Velocity | 70-89 Mtrs./Sec. |

| Color | As per client requirement |

| Delivery Time | 15-20 Days |

| Production Capacity | 4 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Table Type Shot Blasting Machine

- Attain a smooth complexion.

- The aesthetic finish on Die Castings of Aluminum, Zinc & Alloy Steel.

- De-sanding & descaling of castings and forgings.

- Preparation of Surface for Protective coating.

- Removal of heat-treated scales.

Technical Specification Table Type Shot Blasting

| Model | ASBMF-750 | ASBMF-1200 | ASBMF-1800 | ASBMF-2440 |

| No. of Swing Table | One | One | One | One |

| Diameter of Swing Table | 750mm (30″) |

1200mm(48”) | 1800mm(72″) | 2440mm(96″) |

| Maximum Load on Table | 350 kg | 750kg | 2500 | 4500 |

| No. of Blast Wheel | One | One | One | One |

| Size of Blast Wheel (mm) (Dia x Width) | 300mm X 63mm | 500mm X 63mm | 500mm X 63mm | 500mm X 63mm |

| H.P. of Blast Wheel | 7.5 | 15 | 25 | 20 |

| Shots Flow Rate (Kg. / Hour) | 6500 | 9000 | 15000 | 12000 |

| Dust Collector Type | Fabric Type Bag | Fabric Type Bag | Fabric Type Bag | Fabric Type Bag |

| Dust Collector Capacity (CFM) | 1200 | 2000 | 3000 | 4500 |

| Shaking Of Bags | Manual | Mechanical | Mechanical | Mechanical |

| Total H.P. Required | 12 | 23 | 36 | 56 |

| Loading Height (mm) | 1125 | 950 | 950 | 1200 |

| Max. Job Height (mm) | 300 | 600 | 1000 | 1060 |

Dimension of Machine with Dust Collector

| Measurement | Single Door |

Double door |

Single Door |

Double door |

Single Door |

Double door |

Single Door |

Double door |

| L. mm | 2700 | 4050 | 4500 | 6350 | 6400 | 9400 | 10500 | 13500 |

| W. mm | 3450 | 4350 | 4300 | 4300 | 5900 | 5900 | 6500 | 6500 |

| Ht. mm | 4100 | 4100 | 4300 | 4300 | 5300 | 5300 | 5750 | 5750 |

Dimension of Dust Collector of Swing Table Shot Blasting Machine

| L mm | 1200 | 1450 | 1310 | 1660 |

| W mm | 970 | 1310 | 1810 | 2540 |

| Ht mm | 2460 | 3700 | 3750 | 5630 |

Floor Space Reqd. (approx) For Swing Table Shot Blasting Machine With 2 doors opened at 180 Degrees

| L mm | 4850 | 6800 | 9600 | 13500 |

| W mm | 3500 | 4500 | 6000 | 7000 |

Table Type Shot Blasting Machine consists of one / two rotary tables for the loading of the component. This table mounted on the door swings inside the cabinet, so it is also called a swing table type shot blasting machine and the blast wheel on the top cleans the component. The table rotates in a clockwise and anticlockwise direction to ensure the thorough cleaning of the blasting surface by the blast wheel. The component needs to be kept manually upside and down again and again so that to cover the bottom of the component also in the shot blasting machine.

The Table shot blasting machine is also called a Swing Table Shot Blasting Machine consists of one or two rotary tables for the loading of the component. This shot blasting table ascends on the door swings the inner surface of the cabin and the blast wheel on the top cleans the ingredient. The rotation of the swing table can move both sides like a clockwise and anticlockwise route to ensure the perfect cleaning. The ingredient must be kept upside down and thereafter shot blast should be cleaned to cover the bottom of the component.

It consists of a round table over which, the material or ingredients to be blasted are kept and the swing table rotates vertically, therefore, exposing the components to the blast stream by blast wheel. These Table type shot blasting machines also have another table hinged to them in order to reduce the cycle time. The second part of the table is on the other side of the opening which is offloaded and loaded when the blasting is in procedure on the first one. Our Table Shot Blasting Machines are available at a very competitive price.

Table Shot Blasting Machine is a general-purpose machine used for larger-sized medium or heavyweight casting, forging, heat-treated work, welded and bolted structures. Parts like engine blocks, transmission housings, head wheels, crankshafts, etc can be blast cleaned. Table Airless Shot Blasting Machine stands on high functionality, durability, effectiveness, finishing and has a long operational life. Our machine is hence acknowledged and demanded by our customers in the global markets among our competitors.

Features of the table Shot Blasting Machine

- Rustproof body

- Strong construction

- Smooth operation

Table Type Shot Blasting Machine Manufacturers in United States, Germany, Gulf & Australia

Micro Blaster is the best Table Type Shot Blasting Machine manufacturers in United States, Germany, Gulf & Australia. We are also a Manufacturer & Supplier of all type of Sand Blasting Machine, Shot Blasting Machine, grit blasting machine, Sand Blasting Cabinet, suction blasting cabinet, Sand Blasting Room, Sand Blasting Nozzles, thermal Spray gun, Metalizing gun, zinc spray gun, flame Spray gun, arc Spray gun & abrasive media in United States, Germany, Gulf & Australia at a low price with the best quality for sale.

Related Product

© 2025 All right reserved.