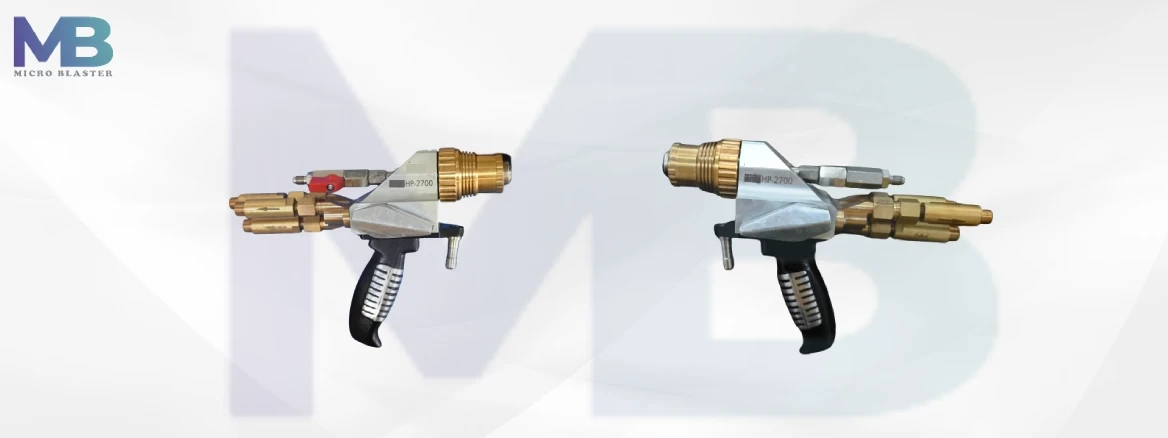

HVOF GUN

Specifications of HVOF GUN

| Model | Hvof Gun |

| Power Supply | 110V, 1P, 60Hz |

| Weight | 1.83 Kg |

| Hose Length | 7.5m |

| Control Panel Dimension | 1570x610x200mm |

| Color | As per client requirement |

| Delivery Time | 15-20 Days |

| Production Capacity | 5 |

| Packaging Details | Polly Pack With Bubble Packing |

Application of HVOF GUN

- Hydropower: Francis turbine, Pelton turbine, Seat turbine, etc.

- Thermal power includes ID fans, barrels, boiler tubes, etc.

- Aviation - landing gear

- Rolls, the paper industry.

- Shafts, Bearing, Rollers, and Rings in general

- Valves, such as ball valves and gate valves.

HVOF Gun is a thermal spray gun system. High-velocity oxide fuel thermal spray gun employing the combustion of gasses also liquid. Discharge gases similarly hydrogen together with a liquid heat source similarly kerosene are utilized. Fuel together accompanied by oxygen mix also atomizes accompanied by combustion space in case so as observes the proper combustion method also pressure mandated for coating.

HVOF spray Gun contained an extremely high acceleration for HVOF coating process. This high acceleration is employed to drive molecules at quick velocity previous to moving onto coating surface. Lofty combustion pressure together accompanied by high velocity of gas & powder results in high coating grade In the Hvof spray coating function.

The HVOF process’s essential advantages are hence the high velocity of the strategy incorporates quite a high coating density also lower oxide scope. The lower oxide range is a consequence of acceleration of molecule consuming more unreasonable duration after only warmth origin. Together accompanied also caused by the lower flame spray gun warmth (around 3,000 C) of warmth conception approximated accompanied by unconventional processes.

Specifications of HVOF Gun

| Fuel Gas | Propane, Propylene |

| Rated power | 110 KW |

| Porosity | 1% |

HVOF Coating

HVOF Spray coating is an extremely wide coating because of high acceleration in squeezing rather than pressure together with too yields the most eminent adhesive stability.

HVOF Coating process, primarily operated coating materials are Nickel & Cobalt-based, Iron-based alloys, Carbides & Cermets powder. For extremely wide coating carbide operations in an extra 6mm.

HVOF spray gun is operated for high-temperature applications, chemical resistance, rust, wear resistance sliding, together with abrasive.

In HVOF a blend of gaseous or liquid energy with oxygen is provided into an explosion enclosure combusted constantly together with ignited. For the expedition of burning gasses at tension, 1 MPa converging-diverging nozzles are operated. Boiling gasses transit via a consecutive passage also encroach on the factor.

In HVOF Spray gun and thermal spray gun usage, fuel can gas similar to raw gasses also acetylene, hydrogen, methane, also propane. together with liquid fuel is similar to kerosene.

The jet velocity at the entrance of the nozzle (>1000m/s) improves the acceleration of sound. A powder feedstock is penetrated into the gas stream to accelerate the powder until 800 meters per second. The stream of burning gasses together with powder is supervised in the direction of the surface on which coating is demanded. Powder partway melts together with touches on the substrate. An HVOF spray gun or thermal spray gun arises HVOF thermal spray coating encloses elevated bond force to lower porosity.

HVOF coating may be dense 6 to 12 mm. This primarily operated material namely ceramic also metallic layers. HVOF Spray Gun is numerous prosperous for the coating of carmet materials (WC-Co).

Benefits of HVOF Coating

- Coating benefit

- More heightened density (Lower porosity).

- Improved rust barrier.

- More elevated hardness ratings.

- Improved wear resistance.

- Higher bonds also have cohesive strength.

- Dropping oxide content.

- More irregular unmelted particle content.

- Greater chemistry also phase retention.

- Wider coatings.

- Smoother as-sprayed surface.

Features of HVOF Gun

- The capability to run on high-octane fuel produces new coatings also application chances.

- Coating goodness also homogeneity are perfect.

- Particle speed grows as the combustion chamber pressure increases.

- The coating has high wear resistance.

- When compared to further thermal spray methods, this one has a more elevated microhardness.

- Bond strengths in lots of 80 MPa are common (10000 psi).

Properties of HVOF Coating

- For heightened-quality wear-resistant coatings, this is the method to use.

- Thermal spray coatings with the most increased density.

- Awesome adherence.

- Uniform Coating with Extremely Increased Bond Strength.

- Superior Resistance to Wear (Carbides).

- Rust Resistance is Outstanding.

- Ignoble-temperature application.

- Relatively Low Residual Stresses.

- Impact Resistance Increased.

- Residual Stress: Neutral to Compressive (Greater thickness capability).

HVOF Gun for Sale in United States, Germany, Gulf & Australia

Micro Blaster is the Manufacturer and Supplier of Hvof Gun, Electic Arc Spray Gun, Thermal Spray Gun, zinc spray gun, Metal spray Guns, Wire Flame Spray Guns, acoustic chamber, Sand Blasting Machine, sand blasting safety equipment, sand blasting chamber, Automatic blasting Machine, vacuum blasting machine, bench top sand blasting cabinets, granite engraving machines, shot peening machines, pressure blast Cabinet, grit blasting machines, Air compressor, abrasive media also dust collector in United States, Germany, Gulf & Australia at a low cost for sale.

Related Product

© 2025 All right reserved.