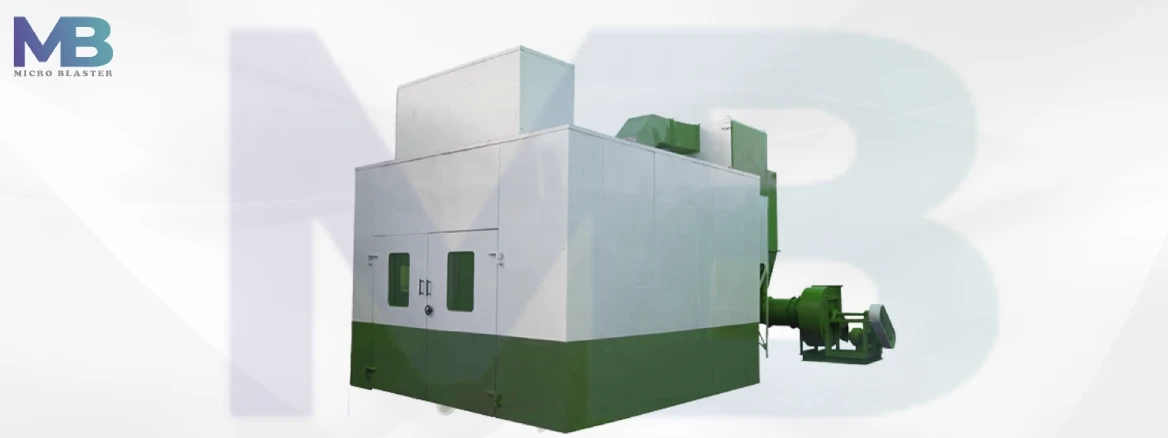

Acoustic Chamber

Specifications of Acoustic Chamber

| Material | Mild Steel |

| Voltage | 240V |

| Shape | Rectangular |

| Usage | Sound Reflectors |

| Color | As per client requirement |

| Delivery Time | 2-3 Weeks |

| Production Capacity | 2-3 |

Application of Acoustic Chamber

- Separate floors.

- Connections for power and light.

- Ventilation.

- Control over humidity and temperature.

- Sleeves for instruments.

- Working floors, single and double sound doors, and control supports.

An acoustic chamber in United States, Germany, Gulf & Australia is commonly utilized in sound transmission to conduct operations in “free field” conditions, free-field implication that there are no reflected signals. The interior of an acoustic chamber is very peaceful, with typical turbulence levels in the 10 – 20 dB limit.

This thermal spray booth or thermal spray acoustic chamber is performed with the interior surfaces lined with perforated sheets and glass wool providing absorption of the incident sound effectiveness, making them echo-free. Intestinal coverings are covered by powder flame spray gun in subsistence with strong sound-comprehension components; the acoustic chamber in United States, Germany, Gulf & Australia is crammed with “characterizations” tiles.

Thermal spray acoustic chamber in United States, Germany, Gulf & Australia practices combine measuring the repetition response of diaphragms and amplifiers. Thermal spray acoustic chamber in United States, Germany, Gulf & Australia practices combine measuring the repetition response of diaphragms and amplifiers. We have implemented an extraordinary venturi contour in a thermal spray acoustic chamber in United States, Germany, Gulf & Australia that affects a large capacity sufficient air compressor to interchange the dust so the pulse fluttering subsistence approximates the best position.

Thermal Spray Acoustic Chamber

We provide a thermal spray acoustic chamber managed in plasma spray gun coating, which moreover introduces dust and noise generated by your thermal spray coating techniques which can be caused by thermal spray gun, arc spray gun, plasma spray gun, zinc spray gun, metalizing wire, and many others. An acoustic chamber in United States, Germany, Gulf & Australia can be thoroughly customized to accommodate your specific necessities. Features include:

- Inlet silencers (up to 8000 CFM combined).

- 30″ x 42″ viewing window(on the main door).

- 82″ x 84″ double-leaf access main door(can be sliding or 4 leaves respectively as per the requirement of the user).

- Baffles Plate is placed in an air louver at an angle of 60 degrees so that sound cannot come out.

- Galvanized metal sheet wall installation is done of the thermal spray acoustic chamber which has a perforated sheet and glass wool which works as sound consumption.

- The Air louver is placed on the roof of the thermal spray booth for air intake.

- In the thermal spray acoustic chamber manufacturer, a cartridge filter dust collector is used which captures dust or fumes on their external surface.

- A suction hood is placed inside the acoustic chamber which removes airborne grease, fumes, heat, and steam from the air by the abandonment of the air and filtration.

- The suction hood can be of two types like when the object is spherical the back wall of the suction hood is round and when it is rectangular or square then it will be a plain wall. If used for both the purpose by you then there is some bend at the back wall of the suction hood.

- UV 10 roll-down shade.

- Standard firm beige paint, custom colors obtainable.

Characteristics of Thermal Spray Acoustic Enclosure

- Reduction in the intensity of sound

- Liveness

- Fulness

- Clarity

- High absorption coefficient

- Ensemble

- Flutter echos from parallel walls

- Intimacy

- Focus on sound

- External noise

- Texture

- Blend

- Rectangular Practice room

- Warmth

- Brilliance

- Easy to handle, clean, and install

Thermal Spray Booth

The thermal spray booth is also appreciated as the acoustic chamber in United States, Germany, Gulf & Australia is a veteran facility that has been prudently designed and built to accomplish nearly perfect quiet circumstances. Almost comprehensive acoustic enclosure in United States, Germany, Gulf & Australia is confinement is achieved by the establishment of internal coverings of surface made of perforated sheet and glass wool which work as soundproofing, heavy sound-proof availabilities. Within the acoustic chamber manufacturer, the external vibration of sound is not sanctioned to break in and sound deliberations off intestinal thermal spray booth frames cannot occur.

The interrupted floor of the thermal spray booth is fabricated from a metal sheet so that more disquieting equipment, up to 50kg, can be contained. The inner receptacle of the thermal spray acoustic chamber manufacturer utilized in plasma spray gun coating is established on springs to neglect the transmission of inconstancy which runs underneath the thermal spray acoustic chamber in United States, Germany, Gulf & Australia. This thermal spray acoustic chamber in United States, Germany, Gulf & Australia allows sound power levels to be accurately determined, frequency recognition to be introduced.

Acoustic Chamber Manufacturer in United States, Germany, Gulf & Australia

We are leading Manufacturers, Exporters, and Suppliers of Acoustic Enclosure in United States, Germany, Gulf & Australia. We also provide a shot blasting cabinet, blast rooms, sand blasting machine, portable sand blasting machine, grit blasting machine, etc. at an affordable price. We propose some abrasive forecasters such as copper slag, garnet sand, quartz stone, steel grit, aluminum oxide, glass beads, steel shot, powder feeder, etc. which are appropriated by blasting machines. Moreover, a team of our quality controllers accompanies a series of quality tests on the entire range to seek out whatever possible mistake. In number with international set pennants, we provide the entire pasture of acoustic enclosure in United States, Germany, Gulf & Australia of various dimensions and at industry influencing prices.

We have fortunately extended its establishment in the market owing to the proposed dignified quality array of the acoustic chamber in United States, Germany, Gulf & Australia. The proposed acoustic enclosure manufacturer, appropriating preferred essence raw-material and the most advanced technology. We are an acoustic chamber manufacturer in United States, Germany, Gulf & Australia at the best price. For coating on the object, we use a thermal spray gun, flame spray gun, wire flame spray gun, arc spray gun, zinc spray gun, plasma spray gun, etc. at an inexpensive price in United States, Germany, Gulf & Australia, and other countries including Kuwait, Dubai, UAE, Oman and other.

Related Product

© 2025 All right reserved.