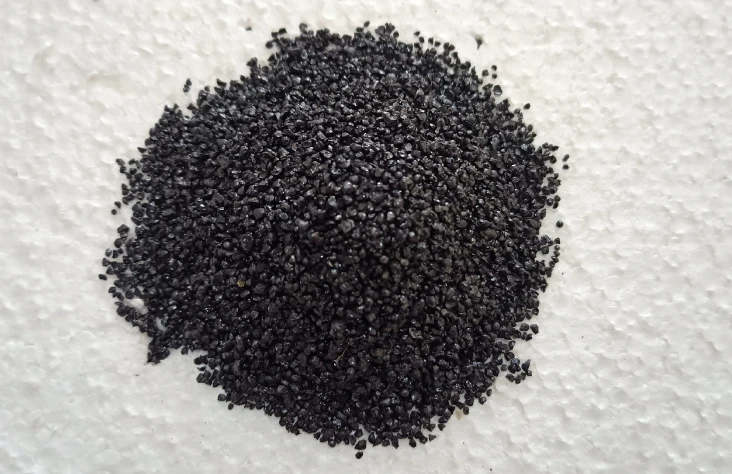

Copper Slag

Specifications of Copper Slag

| Usage/Application | Sand Blasting & Shot Blasting |

| Type | Metallic Abrasives |

| Material | Copper Slag |

| Form | Powder, Granular |

| Grade | Chemical Grade |

| Color | Black |

| Delivery Time | 15-20 Days |

| Packaging Type | Bag, Jumbo Bag |

| Packing Size | 25 kg, 50 kg, 1 ton |

Application of Copper Slag

- Sand blasting machine, Surface Prep

- Grinding Wheels (20/50 Medium)

- Corrosion Cleaning

- Cement Additive

- Garment & Textile Blasting

- Jean & Clothing Sandblasting

- Offshore oil pipeline blasting

- Waterjet Cutting Deepsea Structures

- Roofing Granules – 12/30 for tab shingles, 40/120 for felt also polyester roll roofing

- Pipeline Shot Blasting

- Golf Course Filler – sandbags for artificial turf (30/60)

- Additive to create high-density concrete for nuclear shielding (40/120)

- Paints and Coatings

- Blast Cleaning

- Asphalt anti-skid additive (30/60)

- Slag Wool Insulation

Copper Slag Grit

Copper Slag grit is an energetic abrasive frequently utilized in new steel and steel sustaining applications. Its bulk density and angular shape give it an aggressiveness that gives clean, fast-cutting action, considerably improving production rates.

Copper Slag Abrasive Media

The abrasive blasting process, one of the surface preparation method in shipbuilding and ship repair industries is marked as the major significant sources in the generation of waste; because it is mandatory to process the surface preparation before painting process in shipbuilding or for the removal of the old paint including primer coating from the surface of the steel in ship repair. During the copper slag grit blasting operation environment in the vicinity of the working areas is polluted by a fine dust of the abrasive media which is used, paint, metal chips, and toxic metals.

Specifications of Copper Slag

| Material | Crepe Paper |

| Color | Milky white & Off white, White |

| Width(mm) | 24,48, mm |

| Length(m) | Up to 30 m |

| Temperature | 60 to 180-degree celsius |

| Adhesive type | Aggressive rubber, Raisin solvent based |

| Hardness on Moh’s Scale | 6-7 Moh’s PH |

| Electrical Conductivity | 2 ms/m |

| Granule Shape | Angular, Sharped Edges, Multi Faced |

Most of the Shipbuilding and Ship repair industries had started replacing copper slag grit as abrasive media with environment-friendly media. Therefore, replacement of conventional production methods i.e. blasting using copper slag grit with less contaminating, environmentally safe, and alternative processes that do not or have less effect on human health and the environment is essential. In this work, the harmful effects of abrasive-blasting materials like copper slag grit, iron shots used for surface preparation are investigated by considering the impact effectiveness of the material on human beings and the environment. The results of is outcome bearing in mind the blasting efficiency, cost, and pollution caused by the blasting media. The reason for alternating the present blasting material is to decrease the amount of waste and pollution.

Applications for Iron Silicate Copper Slag

- Sand blasting machine, Surface Prep

- Grinding Wheels (20/50 Medium)

- Corrosion Cleaning

- Cement Additive

- Garment & Textile Blasting

- Jean & Clothing Sandblasting

- Offshore oil pipeline blasting

- Waterjet Cutting Deepsea Structures

- Roofing Granules – 12/30 for tab shingles, 40/120 for felt also polyester roll roofing

- Pipeline Shot Blasting

- Golf Course Filler – sandbags for artificial turf (30/60)

- Additive to create high-density concrete for nuclear shielding (40/120)

- Paints and Coatings

- Blast Cleaning

- Asphalt anti-skid additive (30/60)

- Slag Wool Insulation

Advantages of Copper Slag

- Very high cleaning speed

- Very low dust level

- Lower abrasive consumption

- Recyclable

- Crystalline silica levels are less than 1%

Copper Slag Grit Manufacturer in United States, Germany, Gulf & Australia

We are the leading Copper Slag Grit Manufacturer in United States, Germany, Gulf & Australia. We offer an abrasive shot, Steel Shot, SS Shot, Steel Grit, Garnet sand, Quartz shot, Aluminum oxide, glass beads blasting for stainless steel, etc, and a qualitative range of industrial steel abrasive products.

To enable us to quote for your requirement, kindly give us the following info –

1. Particle size required (You may choose from above or give your own range)

2. Packing required

3. Loading permissible per 20’ HD FCL, if in containers

4. Quantity required with a delivery schedule

5. Destination port

6. Payment terms

7. Discharge rate at the destination, if in break-bulk

8. Any other point which may impact the quote

We can also offer ungraded material for shipments in bulk in any quantities as desired by our buyers on FOB or CNF FO basis terms.

Related Product

© 2025 All right reserved.