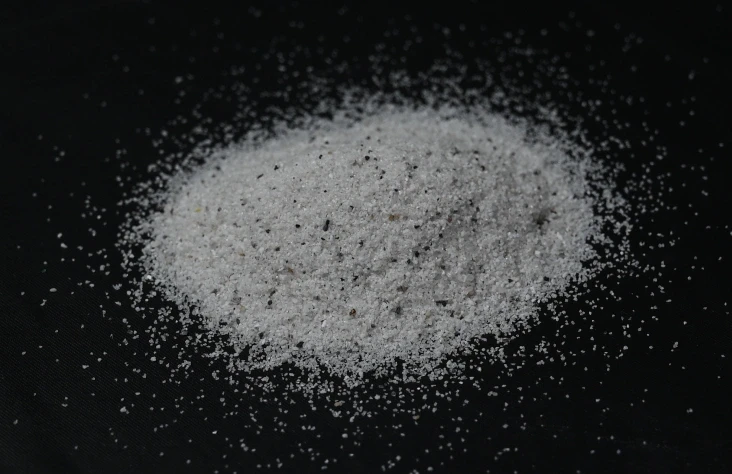

Aluminum Oxide

Specifications of Aluminum Oxide

| Material | Aluminum oxide |

| Size | 0.125 - 2.00 MM |

| Specific Gravity | 3.9 g/ml |

| Usage | Sand Blasting / Shot Blasting |

| Packaging Size | 25 Kg / 50 Kg / 1 Ton |

| Packaging Type | HDPE Woven Gunny Bags |

| Transport Type | Land / Sea / Air Transport |

Application of Aluminum Oxide

- Surface preparation and paint removal in abrasive blasting are accomplished with aluminium oxide.

- In order to assure the performance and adherence of coatings, aluminium oxide is also utilised for etching.

- Applications for it include coating, sandblasting, high-pressure strength, abrasion resistance, and corrosion resistance.

- In addition to being utilised as an abrasive media in blast cleaning, aluminium oxide is frequently employed in ceramics, sandpaper, and anti-slip surfaces.

Aluminum oxide grit may be a clear surface of the substrate at double the speed as sand without all the well being danger. Industrial grit is out there in two types one is virgin grit and therefore the second is commercial grit. Virgin grit is often reused quite 6-7 times easily. And commercial grit is employed 2-3 times. It produces less dust while use. Virgin grit oxide (aluminum) is costlier than commercial grit.

It is often used easily in portable sand blasting machine and wheel blasting machine. to gather and reuse al mostly blasting cabinets and blast room systems are used. In portable blasting machines cleaning or blasting wiped out an open area so it's hard to gather blasting media for reuse.

Sand Blasting nozzle size is additionally considered while choosing alumina size for blasting. the dimensions of blasting media use depend upon the dimensions of the nozzle. If alumina size is large it makes chock the nozzle and blasting not done.

Commercial Aluminum Oxide Grit

An angular, durable blasting abrasive, Commercial aluminum grit machine is often recycled repeatedly. It's the leading widely used abrasive grain in sand blasting finishing and surface preparation due to its cost, longevity, and hardness. Harder than other commonly used abrasive blasting, alumina grit powder penetrates and cuts even the toughest metals and splintered carbide.

Commercial Al used as a grinding and polishing abrasive could also be an economical, quality, efficient media for tumbling operations that require quick edge rounding, surfacing finishing, or cleaning.

Chemical Composition

| Index | Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO |

| Typical value | 95.53 | 1.26 | 0.52 | 2.2 | 0.39 |

Types of Aluminum Oxide Grit Available

- White Aluminum Oxide.

- Brown Aluminum Oxide.

- Black Aluminum Oxide.

- Commercial Aluminum Oxide.

- Virgin Aluminum Oxide.

Applications

- Paint stripping

- Abrasion resistance

- Slurry polishing

- Wear resistance

- Grinding

- Paint filler

- Surface Preparation

- Etching, Carving, Gouging

- Coated Abrasives

- Monument Blasting

- Non-Slip Grit for Epoxy and Resins

- Sandblasting – works great on metal.

- Grinding Anti Skid Flooring

Properties of Aluminum Oxide

- Grades 12 through 1200 available

- Mohs 9 hardness

- Tough & durable, low friability, fast cutting

- Can be recycled multiple times

- Sold in a variety of packaging options: Bags, Drums, Super Sacks

- Samples available for testing prior to purchase

- Sandblasting, etching, carving, surface preparation, anti-slip

Aluminum Oxide Grit Manufacturer in United States, Germany, Gulf & Australia

Micro Blaster is one of the best Aluminum Oxide Manufacturer in United States, Germany, Gulf & Australia. We also provide Sand blasting machine, Shot blasting machine, Grit blasting machine, thermal spray gun all over the world with the best quality. We have the best portfolio of abrasives at the best price to give our customers. Contact Us.

Related Product

© 2025 All right reserved.