Sand Blasting Machine in China

Specifications of Sand Blasting Machine in China

| Product | Sand Blasting Machine |

| Material | Mild Steel |

| Machine Type | Portable and Cabinet |

| Grade | Automatic, Semi-Automatic, Manual |

| Compressed air (80 psi) | 45 Cfm to 217 Cfm |

| Voltage | 220-240 V | 50 Hz |

| Max. Pressure | 10000 PSI |

| Power | 10 HP |

| Brand | Micro Blaster |

| Color | As per client requirement |

| Delivery Time | 7-10 Day |

| Production Capacity | 4 Machine |

| Packaging Details | Polly Pack With Bubble Packing |

Application of Sand Blasting Machine in China

- Construction & Infrastructure: Blast concrete for better paint or waterproofing adhesion, clean steel beams, remove graffiti, and refurbish tunnels and bridges.

- Marine & Shipyards: Clean ship hulls, anchors, and deck equipment. Remove marine growth, salt, and rust without damaging the structure.

- Automotive & Restoration: Used to strip paint and rust from chassis, bodywork, wheels, and precision engine parts prior to repainting or repair.

- Metal Fabrication & Foundries: Clean castings, derust forged tools, smooth weld seams, and prepare surfaces before galvanizing or painting.

- Oil & Gas Sector: Blast pipelines, tanks, and refinery components. Essential for corrosion protection in high-risk environments.

- Aerospace & Defense: Clean turbine blades, frames, and mechanical components with controlled abrasives.

- Decorative, Art & Restoration: Engrave glass, etch stone, and texture metal or wood for signage and interior design.

Sand Blasting Machine in China: Comprehensive Guide

A sand blasting machine in China (abrasive blasting equipment) shoots abrasive media, such as steel grit, garnet sand, or glass beads, at high velocity onto surfaces using compressed air or centrifugal wheels. This removes unwanted layers like rust, paint, scale, mill scale, or dirt, and creates a textured surface ideal for applying new coatings, sealants, or finishes.

Common terms include sandblasting, shot blasting, wet blasting machine, and abrasive blasting machine. Shot blasting typically uses a spinning wheel to project metallic abrasives, while sand blasting uses air or suction to fire various media. These machines perform much faster and cleaner than manual scraping or grinding, making them essential in China’s fast-paced industrial environment.

China is a global leader in manufacturing and infrastructure development. From buildings to high-speed railways, and shipyards to automotive plants, countless industries rely on clean and prepared surfaces. A sand blasting machine in China provides a fast, efficient way to remove rust, old coatings, grime, and mill scale while preparing surfaces for painting, coating, or finishing.

Components of a Sand Blasting Machine

A sand blasting machine is built using several key components that work together to perform abrasive cleaning, surface preparation, and finishing tasks. Each part has its own role in ensuring the efficiency, safety, and effectiveness of the blasting process.

- Blasting Hopper/Pressure Pot: The sand blasting hopper, also called the pressure pot, is the main tank that stores the abrasive material. It is made of strong steel and designed to hold the material under high pressure. The size of the hopper varies depending on the type and scale of the blasting work. Its main job is to feed the abrasive into the air stream that goes to the nozzle. It is sealed tightly to prevent leaks and ensure smooth operation.

- Abrasive Media: The abrasive material is what actually does the cleaning or surface preparation. Different abrasives are used depending on the application. Common types include:

- Garnet Sand - for general purpose and eco-friendly blasting

- Aluminum Oxide - for aggressive cleaning

- Steel Grit and Steel Shot - for heavy-duty industrial cleaning

- Glass Beads - for smooth finishing

- Soda (Sodium Bicarbonate) - for delicate surfaces

- Copper Slag - for rust removal

- Plastic Media - for softer surfaces like aluminum

- Walnut Shells - for eco-friendly and gentle blasting

Choosing the right abrasive is important for both the quality of the finish and the safety of the process.

- Air Compressor: The air compressor provides the high-pressure air needed to move the abrasive material through the machine. It powers the entire blasting process. The compressed air mixes with the abrasive in the hopper and pushes it through the hose to the nozzle. It’s important that the compressor has enough capacity (usually 5–8 bar or 70–120 PSI) to match the blasting machine’s requirements.

- Blasting Hose: The sand blasting hose is a durable, high-pressure-resistant tube that connects the blasting pot to the nozzle. It carries a mixture of air and abrasive material. Since it deals with fast-moving, rough particles, the hose is usually made of thick rubber or polyurethane. The length and diameter of the hose may vary depending on the work area and pressure needs.

- Blasting Nozzle: The nozzle is one of the most important parts of the machine. It controls the speed and pattern of the abrasive stream that hits the surface. It is usually made from tungsten carbide, boron carbide, or ceramic to resist wear. There are different types of nozzles, such as:

- Straight Bore Nozzles – for spot cleaning and precision work

- Venturi Nozzles – for a wider spread and higher efficiency

The choice of nozzle affects both productivity and abrasive use.

- Abrasive Metering Valve: The metering valve controls how much abrasive enters the air stream. Too much abrasiveness can cause wastage, while too little reduces cleaning power. A good metering valve ensures a consistent flow, reduces material use, and improves blasting quality. Common valve types include flat sand valves, Thompson valves, and pinch valves.

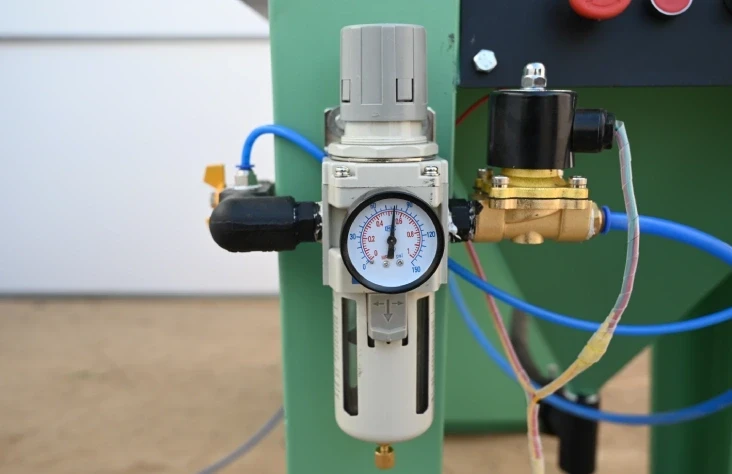

- Moisture Separator: A moisture separator removes water and humidity from the compressed air. Moisture can cause abrasives to clump, block hoses, and damage equipment. Especially in humid climates, a dryer or separator is essential for preventing system failure and ensuring clean, dry blasting operations.

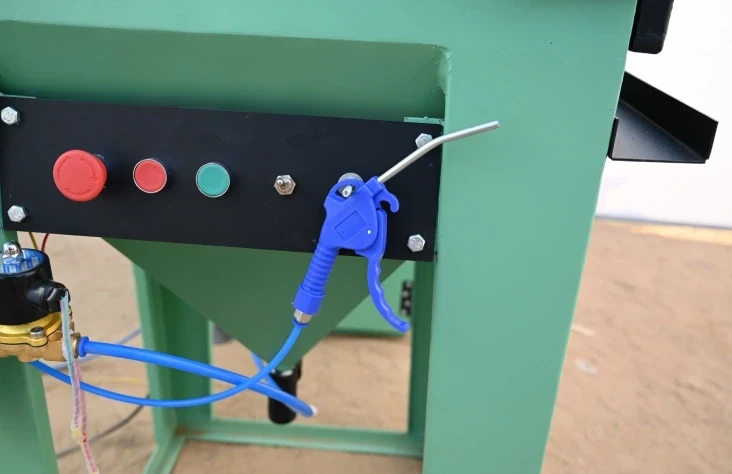

- Remote Control Switch or Deadman Handle: Remote control valve safety equipment is located near the nozzle and allows the operator to instantly start or stop blasting. Known as a deadman handle, it automatically stops blasting if the operator lets go. This is critical for preventing accidents and ensuring the operator’s control over the machine at all times.

- Dust Collector: Blasting generates a large amount of dust, especially in dry blasting operations. A dust collector or dust extraction system removes fine dust from the work area, improving visibility and operator safety. There are different types of dust collectors:

- Cartridge Filters

- Bag Filters

- Cyclone Separators

This component is essential for indoor work or enclosed systems like blast cabinets and rooms.

Benefits of Using Sand Blasting Machines

- Fast and Efficient: Cleans surfaces in less time compared to manual methods.

- Improves Surface Adhesion: Coatings, paint, and adhesives stick better.

- Removes Contaminants Completely: Rust, oil, dirt, and mill scale are easily removed.

- Environmentally Friendly Options: Wet and vacuum blasting reduces dust.

- Reduces Labor Cost: Machines work faster and need fewer workers.

- Reusable Abrasive Media: Reduces long-term operation costs.

Sand Blasting Machine Manufacturer in China

Micro Blaster is a top sand blasting machine manufacturer in China, also offering sand blasting equipment across the globe. Our sand blasting machines are priced competitively, making them more affordable than many other industry options. The price of each sand blasting machine varies based on the type and capacity of the abrasive tank used. We offer a complete range of sand blasting machines, including portable sand blasting machines, sand blasting cabinets, pressure blasting cabinets, sand blasting rooms, dustless blasting machines, internal pipe blasting equipment, vacuum blasting machines, automatic sand blasting machines, laser cleaning machines, granite engraving machine, wet blasting machines, and more. In addition, we supply high-quality sand blasting spare parts, safety gear, dust collectors, and all types of abrasive media to meet diverse industry needs.

© 2025 All right reserved.