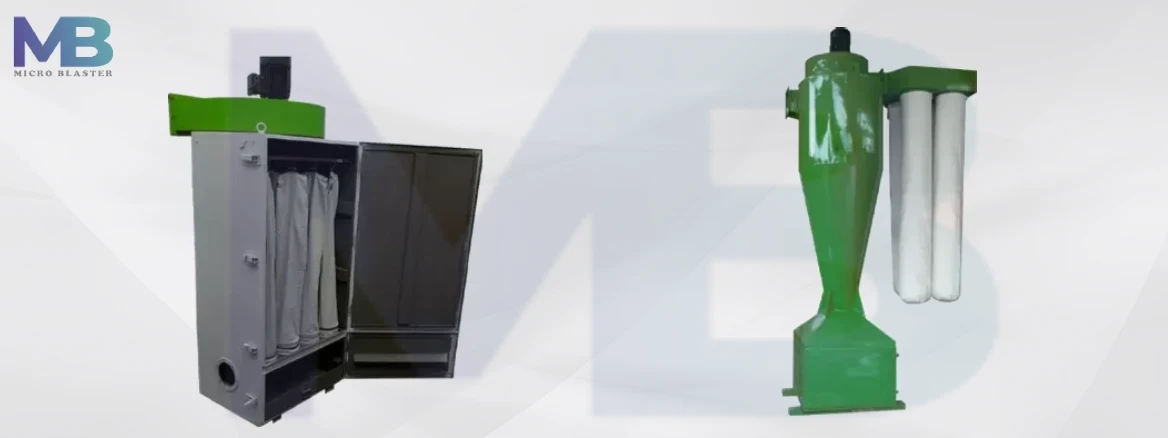

Fabric Bag Dust Collector

Specifications of Fabric Bag Dust Collector

| Type | Fabric Bag Dust Collector |

| Material | Mild Steel |

| Type Bag | Fabric Bags |

| Motor Power | 0.5 - 5 H.P. |

| Fan Capacity | 300 - 1200 CFM |

| Packaging | Bubble Wrapping / Box |

| Transport | Land / Sea / Air |

| Usage | Collect Fine unnecessary particle |

Application of Fabric Bag Dust Collector

- A dust collector purifies the air in your factory by removing contaminants like dust, waste, gases, and chemicals.

- Pre-filter systems commonly employ tiny cloth dust catchers.

- A fabric bag dust collector system includes a blower, dust filter, filter cleaning system, dust receptacle or dust removal system, among other components.

- Small pressure blasting cabinets and suction blasting cabinets both need this kind of dust collection.

In the fabric bag dust collector, individual bags are supported by a metal cage inside the fabric bag which is fastened onto a cell plate at the top of the bag filter. Dirty gas enters from the bottom of the bag filter and flows from outside to inside the bags. The metal cage prevents the collapse of the bag filter.

Filter bags are cleaned by a short burst of compressed air injected through a common manifold over a row of filter bags. The compressed air is accelerated by a sand blasting nozzle mounted at the fabric bag dust top of the bag. Since the duration of the compressed-air burst is very short (0.1s), it behaves as a fast-moving air bubble, traveling the entire length of the filter bag and causing the bag surfaces to flex or move. This flexing or moving of the filter bags breaks the dust cake formed on them, and the layer of dust falls into a sand blasting hopper placed below the dust collector machine.

Specifications of Fabric Bag Dust Collector

| Air Capacity (Cubic Feet per Minute) | 1000-2000 CFM, 2000-4000 CFM, 4000-6000 CFM, 8000-10000 CFM, 10000-15000 CFM |

| Automatic Grade | Automatic, Semi-Automatic |

| Bag Capacity | 12 - 80 Bag |

| Bag Type | Cotton Bag or Non-Woven Polyester |

| Filtration efficiency | less than 40 microns |

| Input Voltage (volt) | 440 |

| Material | Mild Steel, Stainless Steel |

| Micron filtration | 35 |

| Warranty (month) | 12 |

Fabric bag dust collector can work continuously and cleaned without any hurdle in the flow because the burst of compressed air is very small as compared with the total volume of dusty air through the fabric bag dust collector. Due to this continuous-cleaning feature, reverse-jet fabric bag dust collectors are usually not compartmentalized and even allow them to operate at higher air-to-cloth ratios.

This cleaning system works with the help of a digital sequential timer attached to the fabric bag filter. This timer signals the solenoid valve to inject the air into the blowpipe in the fabric bag so that the dust cake could be broken and collected in the storage hopper.

Applications of Fabric Bag Dust Collector

- Woodworking Dust

- Sand blasting

- Shot blasting machine

- Grit blasting

- Ceramics

- Pharmaceuticals

- Chemicals

- Activated Carbon

- Food Processing

- Rubber

Features of the Fabric Bag Dust Collector

- There is high collection efficiency

- It has an optimal air-to-cloth ratio

- Low maintenance cost as it is easy to handle machine

- The online cleaning cycle is thereafter a fixed interval of time

- Antistatic filters option is available

Related Product

© 2025 All right reserved.