Sand Blasting Machine Manufacturer in Japan

Specifications of Sand Blasting Machine Manufacturer in Japan

| Blast Tank Capacity | 150 liters to 500 liters |

| Nozzle Material | Tungsten Carbide / Boron Carbide |

| Nozzle Size | 5 mm to 10 mm diameter |

| Abrasive Media Supported | Garnet, Glass Beads, Aluminum Oxide, Steel Grit, Silicon Carbide |

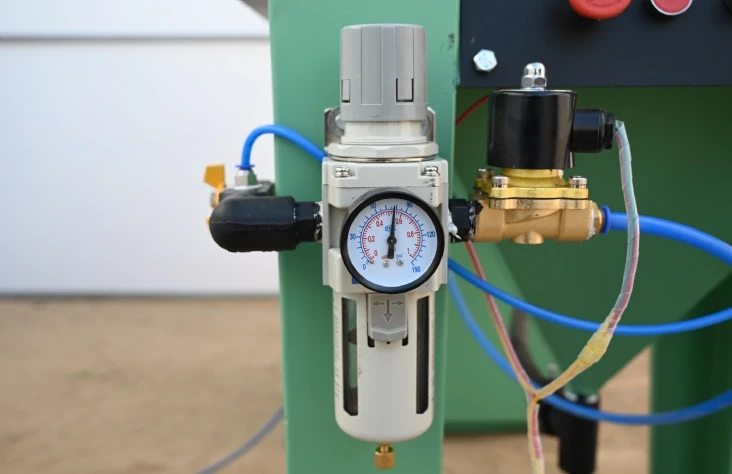

| Operating Pressure | 80 to 120 PSI |

| Air Requirement | 5 CFM (compact models) to 50 CFM (industrial units) |

| Power Source | Pneumatic or Electric |

| Machine Configuration | Portable, Cabinet, Automated |

| Dust Collection System | Bag Filter, Cyclone, or Cartridge-Based Systems |

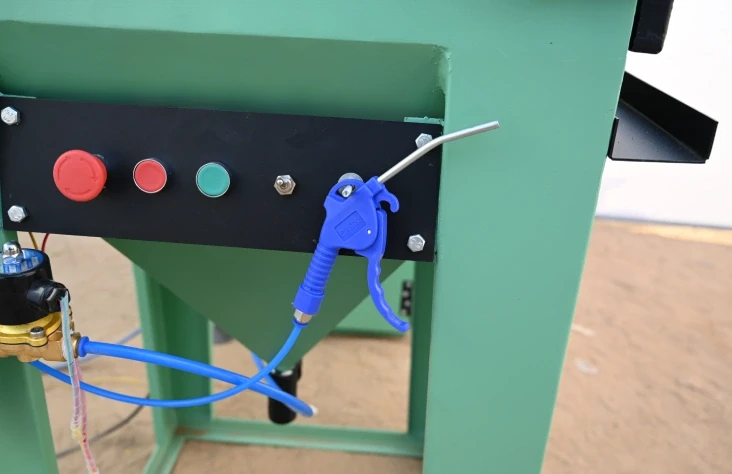

| Control Type | Manual, Semi-Automatic, or Fully Automatic (PLC) |

| Cabinet Size | 900 x 600 x 600 mm to 1500 x 1200 x 800 mm (customizable) |

| Suitable Industries | Automotive, Electronics, Aerospace, Shipbuilding, Steel Fabrication |

Application of Sand Blasting Machine Manufacturer in Japan

- Surface preparation before powder coating or painting

- Cleaning automotive parts and manufacturing tools

- Rust and oxide removal from steel structures and tanks

- Etching and marking on glass or ceramic for decorative purposes

- Deburring and smoothing of precision-machined components

- Restoration of industrial equipment and metal surfaces

Sand Blasting Machine in Japan

In Japan, precision, reliability, and efficiency are essential for all industrial processes—including surface treatment. A sand blasting machine is a vital tool used across industries like automotive manufacturing, aerospace, electronics, and shipbuilding. It helps remove rust, oxide layers, old paint, and other surface contaminants, preparing materials for further processing or finishing.

As one of the leading exporters of sand blasting machines to Japan, we understand the high standards required by Japanese industries. Our machines are engineered for durability, accuracy, and compliance with environmental safety norms.

Working of Sand Blasting Machine

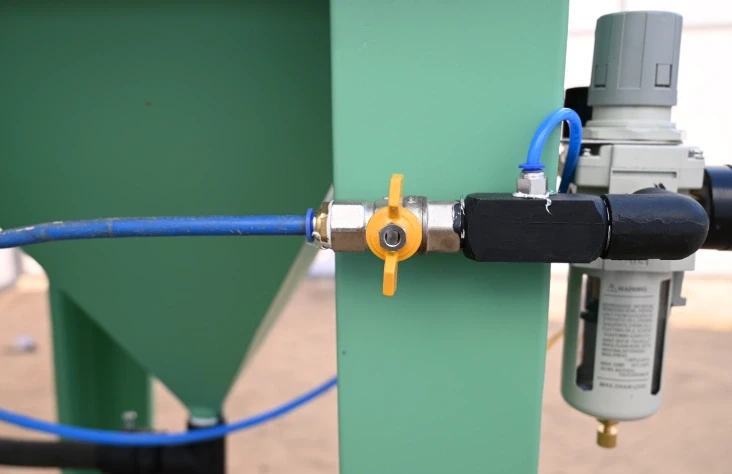

A sand blasting machine works by using a high-pressure air system to accelerate abrasive particles toward a surface. These abrasives strike with force, cleaning or roughening the surface depending on the application. The process can be controlled manually or automated through PLC systems.

Given Japan’s advanced manufacturing environment, our machines are often integrated with features like media recovery systems, advanced filters, noise control, and programmable blasting cycles to meet industry-specific needs.

Types of Sand Blasting Machine

- Pressure Sand Blasting Machine – Designed for heavy-duty cleaning and high-speed operations.

- Suction Sand Blasting Machine – Best suited for delicate surfaces or small parts where lower pressure is required.

- Wet Blasting Machine – Used in cleanroom environments or electronics industries where dust control is critical.

- Automatic Sand Blasting Machine – Fully integrated into production lines, ideal for high-volume precision work.

Types of Portable Sand Blasting Machine

- Portable Sand Blasting Machine P7 150 – Ideal for touch-ups and on-site repair jobs.

- Portable Sand Blasting Machine P7 500– Suitable for medium-duty applications like tool cleaning and component prepping.

- Portable Sand Blasting Machine P7 1000 – Built for large components and on-site construction or shipyard tasks.

Types of Sand Blasting Cabinet

- Suction Blasting Cabinet – Simple and economical; perfect for general maintenance and small parts.

- Pressure Blasting Cabinet – Delivers more aggressive cleaning; used for industrial components.

- Wet Blasting Cabinet – Preferred for aerospace or electronics industries due to low heat and dust.

- Automatic Blasting Cabinet – Customized for high-throughput manufacturing environments.

Sand Blasting Machine Price in Japan

The price of sand blasting machines in Japan depends on the size, technology level, and customization.

- Low price range machines include compact, portable blasters for small jobs and repairs.

- Medium price range systems include cabinet machines with dust control, suited for factory use.

- High price range machines are fully automatic and engineered for continuous production in large manufacturing setups.

We offer flexible configurations and value-based pricing for businesses of all sizes—from local workshops to multinational plants.

Why Choose Us as Your Sand Blasting Machine Manufacturer in Japan

As a trusted global exporter, we serve the Japanese market with sand blasting machines that meet the highest industry expectations.

- Precision manufacturing that matches Japanese quality standards

- Machines compatible with ISO, CE, and RoHS directives

- Low-noise, low-dust models ideal for controlled environments

- Custom automation integration with Japanese production systems

- Long-life components and minimal maintenance design

- Local technical support and spare part availability via our distribution partners

- Proven expertise in serving electronics, automotive, and marine clients in Japan

© 2025 All right reserved.