Sand Blasting Nozzle in India

Specifications of Sand Blasting Nozzle in India

| Product | Sand Blasting Nozzle in India |

| Material | Tungsten Carbide Insert and Aluminium Jacket |

| Orifice Diameter | 5, 6, 8, 10, 12 mm |

| Thread Size | 1/4" BSPT, For Y gun |

| Usage | Sand Blasting Machine |

| Tensile Strength | 100-700 MPA |

| Brand | Micro Blaster |

| Delivery Time | 2-3 Weeks |

| Packaging Details | Polly Pack With Bubble Packing |

| Production Capacity | 20-25 Nozzle |

Application of Sand Blasting Nozzle in India

- Steel / Construction: Used for preparing steel beams, structures, bridges, removal of mill scale, and corrosion.

- Ship Repair: Sandblasting nozzles subjected to intense wear, cleaning ship hulls—boron carbide preferred for extended use.

- Automotive Refurbishment: Cabinet blast systems: blast nozzle must be short and uniformly shaped for parts blasting.

- Infrastructure Maintenance: Cleaning pipelines, concrete surfaces, tower structures, and venturi nozzles used in roof blasts.

- Foundry & Forging: Tens of thousands of parts are cleaned daily, and tungsten or boron carbide nozzles are cost-effective.

- Municipal & Utilities: Removing scale from water conduit,s wet-blasting accessories include nozzle adaptors.

Introduction to Sand Blasting Nozzle in India

The sand blasting nozzle in India holds critical importance for efficient and economical abrasive sand blasting machine operations. Acting as the final point of abrasive acceleration, the nozzle determines cleaning speed, surface quality, media consumption, and wear characteristics.

A sand blasting nozzle, also referred to as a blasting or abrasive blasting nozzle, is the component designed to focus and throw abrasive media at high velocity onto a surface. It is the only wear-critical component in the blasting pot assembly. Typical nozzle components include:

- Nozzle body (steel jacket) to contain abrasive wear

- Throat insert made of wear-resistant materials

- External threads or flanges for attachment

In India, these nozzles are essential to industries like foundries, shipyards, infrastructure, automotive, power plants, and workshops.

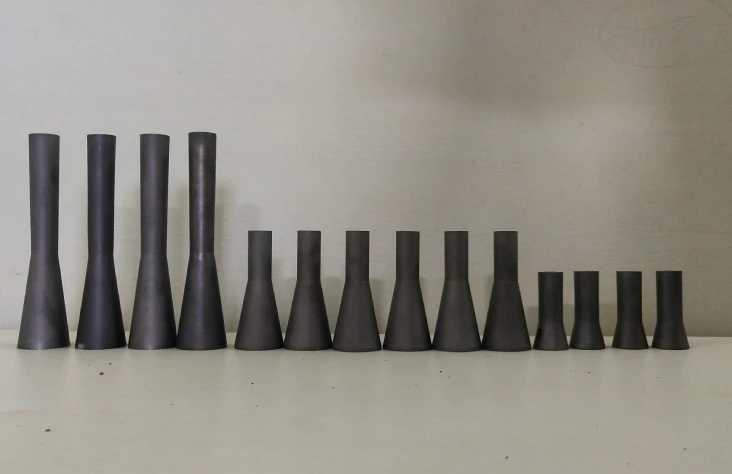

Types of Sand Blasting Nozzles Available in India

- Straight Bore Nozzles: Most common simple cylindrical design. Available in steel sleeves with replaceable ceramic/throat inserts.

- Venturi (Converging-Diverging) Nozzles: Provide accelerated flow speed and reduced turbulent effects, ideal for pressure recovery in large blast setups.

- Wear-Resistant or Super-Venturi Nozzles: Optimized internal profile for laminar flow used in high-pressure applications exceeding 120 PSI.

- Long- and Short-Length Nozzles: Short (75 mm) for confined spaces, long (up to 500 mm) for deep shot or recessed surface cleaning, common in Indian construction and bridge maintenance.

Why Selection of Sand Blasting Nozzle from India

- Cleaning Speed & Efficiency: Nozzle size and internal shape determine abrasive velocity and flow rate. Matching nozzle diameter to blasting pressure and media optimizes productivity, especially vital for Indian contractors operating under tight deadlines.

- Media Consumption: Efficient nozzles project abrasive uniformly, reducing media wastage.

- Wear Life & Replacement: Nozzle longevity equals lower downtime and cost savings. Ceramic and tungsten carbide nozzles last significantly longer, mitigating frequent replacements.

- Surface Quality & Finish: Well-maintained nozzles ensure a consistent abrasive profile, essential to meeting SSPC and Sa2½ standards for coating adhesion, crucial in Indian corrosive environments.

- Energy Use & Safety: Proper nozzle shape and size reduce compressed air consumption. In environments like shipyards or Pharma SEZs, efficient nozzles also contribute to lower noise and dust.

Selecting the Right Sand Blasting Nozzle

- Match to Equipment: Verify nozzle size (3/8″, 7/16″, 1/2″) suits your compressor’s CFM at working pressure.

- Choose Material

- Ceramic for low-budget, low-volume

- Tungsten for general contract work

- Boron or silicon carbide for heavy industrial jobs

- Determine Length: Short nozzles suit spot jobs, long or deep-blasting for inside tubes or ducts common in Indian utilities.

- Verify Threading: Standard ANSI NPT vs BSP ensure compatibility with the blast pot brand.

Sand Blasting Nozzle Manufacturers in India

Micro Blaster is one of the best sand blasting nozzle manufacturers in India, and also a supplier of sand blasting nozzles worldwide. Our sand blasting nozzle price depends on the type and size of the sand blasting nozzle. We provide all types of sand blasting nozzles such as silicon carbide nozzle, tungsten carbide nozzle, boron carbide nozzle, and also deliver all types of sand blasting machines, laser rust cleaning machines, granite engraving machine, portable sand blasting machine, sand blasting hopper, remote control valve, abrasive media, steel shot, steel grit, garnet sand, copper slag etc.

© 2025 All right reserved.