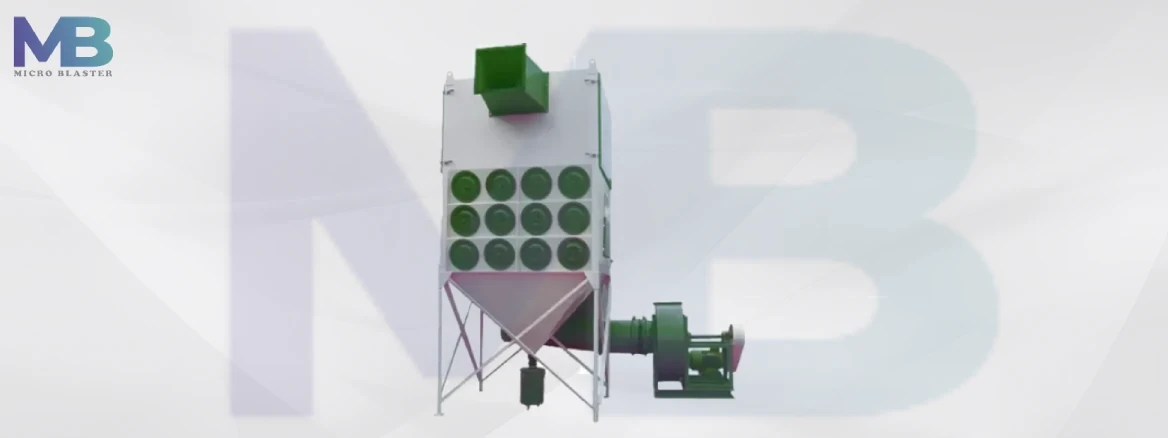

Acoustic Chamber Dust Collector

Specifications of Acoustic Chamber Dust Collector

| Material | Mild Steel |

| Type | Reverse Pulse Jet & Cyclone type Dust Collector |

| Type Bag | Fabric Bag / Pleated Filter |

| Filter Cloth Area | 3 - 20 Sq. Mtr. |

| No of Bags | 02 - 20 Nos. (according to req.) |

| Power | 3 - 10 H.P. |

| Fan Capacity | 500 - 1500 CFM |

| Size | Customized |

| Packaging Type | Bubble Wrapping / Box |

| Transport Type | Land / Sea / Air Transport |

Application of Acoustic Chamber Dust Collector

- Acoustics Chamber For tasks like painting and metalizing that involve high temperatures and a lot of dust, dust collectors are best suited.

- Dust collectors greatly lessen airborne smoke and dust, keeping them away from completed goods.

- As well as collectors that operate differently, such as reverse pulse jet and cartridge collectors, there are also collectors that are specifically created for operations that produce mist rather than dust.

- Centrifugal force, akin to that of a drain, is used by centrifugal collector cyclones to remove dust.

The acoustic chamber dust collector adopted in United States, Germany, Gulf & Australia is a cartridge filter dust collector. Cartridge filter bag dust collector have numerous preferences over conventional bag collectors, like Large filter operations collected in more diminutive overall sizes. We are the manufacturer of Acoustic Chamber Dust Collector at a low price in United States, Germany, Gulf & Australia. The selection effectiveness of a well-designed cartridge filter dust collector is up to 99.9% in succeeding smaller than micron-scale-sized fragments as inadequate as 0.3 microns.

Cartridge filter dust collectors are next-peers bag filter type dust collector utilizing pleated cartridge filters for efficiently comprehending finer dust willingly of filter bags. The Reverse Pulse Jet Pleated Filter system reduces the choking of filters by eliminating concentrated inside the cartridge filter dust collector in conventional interruptions which makes the dust scraps fall down from the outlying surface of the cartridge filters.

Benefits of Pleated Filter Cartridge Dust Collector in United States, Germany, Gulf & Australia

The benefits of a pleated filter cartridge dust collector system are enormous. Industrial features produce the appearance of acoustic chamber dust collector in order to conserve a safe environment. Industries that are exacerbated by a cartridge filter dust collector contains:

- woodworking

- mining

- engraving

- optics

- dental

- metalworking

- laser cutting

- plating

- jewelry

By running our top-quality pleated filter cartridge fabric bag dust collectors, people breathe further pleasantly every day. And customization is conceivable for our cartridge filter dust collector accumulating. Engineers of all variations find the classifications especially useful for the elimination of small particles that uniquely would be snorted.

Industrial Use of Cartridge Filter Dust Collector

Cartridge filter dust collector and fume collectors are well accepted for work stretches that require filtration of very fine crude granulated. Here is some utilization of acoustic chamber dust collector where cartridge filter complements are commonly used.

- Pleated filter cartridge dust collector is operated in paper scrap, rubber grinding, seed processing.

- Grain silos

- A pleated filter cartridge dust collector is concerned with blasting done by sand blasting machine, shot blasting machine, grit blasting machine, abrasive blasting machine, blast rooms, and many others.

- Smoke filtration

- Pharmaceutical

- Welding fume extraction

- Chemical or plastics production

- Abrasive blasting

- Woodworking Fiberglass manufacturing

- Acoustic chamber dust collector operated in solar panel fabrication

- The cartridge dust collector is utilized in chemical processing.

- Industrial acoustic chamber dust collector cartridge filters are operated in Laser and Plasma Cutting, Mining, pharmaceuticals, and various.

- Laser or plasma cutting

- Acoustic chamber dust collector are appropriated in thermal spray gun coating, Flame Spray gun coating, zinc spray gun coating, metalizing spray gun coating, etc.

Cleaning Cycles in Pleated Filter Cartridge Dust Collector

Most utmost pleated filter cartridge dust collectors utilized a pulse jet cleaning cycle to excrete particulate from the filter mechanisms but in some acoustic chamber, the dust collector applies air pressure tank pressure coating 3-4 kg/cm2 in an acoustic chamber dust collector. Some acoustic chamber dust collector use efficaciousness-conserving pulse jet procedures to keep the filters available while sustaining energy and air compressor. A pleated filter cartridge dust collector of the air compressor travels down the filter media, going in the inverse direction from the air consumption.

Acoustic Chamber Dust collector Manufacturer in United States, Germany, Gulf & Australia

We are an acoustic chamber dust collector manufacturer in United States, Germany, Gulf & Australia. We also supply pleated filter cartridge dust collector, thermal spray gun, arc spray gun, cartridge filter dust collector, sand blasting machine, shot blasting machine, grit blasting machine, abrasive blasting machine, blast rooms, dustless blasting machine, suction blasting cabinet, sand blasting cabinet, shot blasting cabinet, portable sand blasting machine, and many other machines in .

Simultaneously with acoustic chamber dust collector, we also supply some abrasive material such as copper slag, glass beads, cut wire shot, aluminum oxide, chilled iron grit, plastic abrasive media, garnet sand, quartz sand, and many others at a low price for sale in United States, Germany, Gulf & Australia.

Related Product

© 2025 All right reserved.